THE ROLE OF WASTE PACKAGE SPECIFICATIONS

AS A FORERUNNER TO ILW REPOSITORY

CONDITIONS FOR ACCEPTANCE

Stephen Barlow, Neil Carr and John Palmer

United Kingdom Nirex Limited

Curie Avenue, Harwell, Oxfordshire, OX11 0RH, UK

ABSTRACT

In the absence of a finalised repository site or design, Nirex, the UK waste disposal agency, is not in a position to issue waste acceptance criteria to those wishing to package waste. Nirex has therefore developed a strategy which facilitates packaging of intermediate level waste by providing guidance through Waste Package Specifications, supported by the formal assessment of specific packaging proposals on a case by case basis. The Waste Package Specifications are comprehensive and cover all aspects of the waste package including dimensions and other key features, performance standards, wasteform, QA and data recording requirements.

The Waste Package Specifications will be subject to periodic review as repository design and safety cases are finalised and will progressively become site and design specific. The Waste Package Specifications will eventually form the basis for Conditions for Acceptance.

The paper describes the basis of the Waste Package Specifications and their continuing development. It details how these have been used in UK waste management practices and illustrates the work done by Nirex to develop and refine generic specification targets. Adherence to this practice has permitted wastes to be packaged for deep disposal with confidence in the absence of a finalised site and safety cases for the repository. Because the process has its basis in a generic repository concept, it remains robust to the siting and timescale of a deep waste repository, and continues to be an important component of the UK's waste management strategy.

INTRODUCTION

United Kingdom Nirex Limited (Nirex) is responsible for developing facilities for the safe disposal of intermediate and certain low level radioactive waste (ILW and LLW) within the UK. In due course, Nirex will issue Conditions for Acceptance (CFA) (equivalent to waste acceptance criteria) and all waste packages will have to comply with these before being accepted for disposal. The acceptance criteria will be determined principally by the safety standards to be achieved, including requirements specified in the authorisation for disposal, but will also take account of design constraints, legal, operational and economic factors.

Since the authorisation will not be granted until very much closer to the commencement of repository operations and waste producers wish to package wastes prior to the availability of the deep repository, Nirex is producing a suite of specifications and guidance documentation in order to permit wastes to be packaged in a form which is compatible with the plans for transport and disposal.

This paper describes the Nirex approach to container standardisation and the role of Waste Package Specifications. It explains how these are used to facilitate the packaging of waste in advance of an operating repository and how Nirex has carried out generic research to develop robust specifications that are not specific to a particular repository design or site.

STANDARDISATION

Standardisation has been shown to produce both economic and safety benefits throughout the waste management lifecycle. Nirex has defined a range of standard waste containers which are suitable for packaging the variety of wastes predicted to arise within the UK and these have been adopted by the UK Nuclear Industry. The number of containers in the standard range has been limited to six as this number is the minimum which best meets the needs of the UK waste packagers.

The standard containers are shown in Table I.

Table I. Nirex Standard Containers

The 500 litre drum, 3m3 box and 3m3 drum are manufactured from relatively thin-walled steel and are not designed to provide any radiation shielding. Handling and storage of these packages requires remote handling facilities and for transport, re-usable shielded transport containers. The use of a re-usable transport container has the major advantage that shielding and containment to meet IAEA Transport Regulations can be invested in the re-usable item rather than the disposable one. The 500 litre drum, 3m3 box and 3m3 drum are described as 'unshielded' containers.

The 4m ILW box will be restricted in radioactivity content to that which can be packaged into an IAEA Industrial Package and as a consequence, shielding can be economically provided within the package itself. The 4m ILW box is described as a 'shielded' container; when filled with waste it is both a transport and a disposal package. The two LLW boxes are also classified as Industrial Packages. Further information on standard containers is available in Reference 1.

BASIS OF WASTE PACKAGE SPECIFICATIONS

Having identified the importance of standardisation, specifications to define the standard containers and set minimum standards of performance for the complete waste package were needed. In the case of an existing disposal facility this would normally be achieved by the issue of CFA, but in cases where wastes are required to be packaged in advance of the availability of a disposal facility (such as in the UK), an alternative method of specifying standard packages had to be constructed.

Nirex, as developer of the ILW disposal facility in the UK, will eventually be able to specify CFA against which all waste packages will have to comply before being accepted for disposal. However, prior to this Nirex has implemented a strategy to facilitate early waste packaging, whilst minimising the risk of future reworking of packages, by providing guidance through a suite of Waste Package Specifications. The specifications provide a basis against which waste packagers can develop packaging proposals and against which Nirex can assess specific proposals and provide advice.

The Waste Package Specifications have been based on the following general principles:

Specifications are based on bounding conditions and form a benchmark against which Nirex can provide advice and assurances. The bounding conditions are derived from design and safety considerations of the generic deep disposal system proposed for the UK.

Specifications are provided on the basis of best practice and will be subject to periodic review as the deep repository project progresses. The intent will be to relax the bounding conditions as results from on-going development programmes into package performance reduces the uncertainty in the behaviour of specific package types during transport, operation and following disposal. In addition, when the repository site and design are confirmed, final safety cases will be established and this will enable Nirex to identify any conservative margins and address the criteria accordingly when issuing Conditions for Acceptance.

CONTENT OF WASTE PACKAGE SPECIFICATIONS

Specifications are provided for:

Waste Package

Specifications have been produced for each of the standard waste packages. The specification is applicable to the waste package as a whole, that is to say, the waste container plus its contents, the wasteform. The specification defines dimensions and key features of the container and sets down minimum performance standards for the complete package. Criteria are specified for activity content, dose rate, heat output, surface contamination, dimensions, lifting feature, mass, venting, integrity, properties of the wasteform, impact and fire performance, stackability and identification. In the case of packages which are also transport packages, additional criteria are specified for applicable regulations (e.g. Transport Regulations).

Following from the principle that specifications should be independent of repository site and design, the Specifications are based on generic repository concepts and safety considerations. The generic concept assumes that both unshielded and shielded waste packages will be handled at the repository, with reusable shielded overpacks being used for the unshielded packages to provide protection to public and repository workers. Disposal packages are handled remotely by overhead crane and emplaced in caverns excavated in the host rock. Safety analyses make reasonable assumptions regarding the efficiency of underground ventilation and filtration systems and the extent of particulate deposition in the event of accident. Specifications also take credit for the predictability of impact release fraction which is offered by cementitious wasteforms. Because of the inherent predictability of these wasteforms, consideration can be given to alternative drop heights if required.

Wasteform

Wasteform specifications have been produced to augment the waste package specifications by specifying in more detail any limits on the contents of packages and best practice for producing a wasteform with the required chemical and physical properties. The specification covers immobilisation of radionuclides, mechanical and physical properties, chemical containment, hazardous materials, degradation processes and wasteform stability, gas generation and nuclear properties.

Quality Assurance

Consistent with company policy and regulatory guidance, a system of quality assurance has been established for all activities which affect the repository safety case and this includes packaged wastes. The purpose of the QA system is to provide the evidence to demonstrate that waste packages comply with a defined specification that can be assessed against future CFA.

The Quality Assurance Specification is mandatory and describes the QA programmes and plans, the Waste Product Specification and the system of verification required to be put in place by the waste packager [2].The Quality Assurance Specification requires that for all activities affecting product quality, waste packagers demonstrate that QA arrangements consistent with the Specification are in place, that these arrangements are being implemented and that appropriate corrective actions are taken where necessary.

Data Recording

Nirex as the developer and operator of the deep repository will need to hold information on each waste package consigned for disposal. The scope and extent of the information to be recorded is defined in the Data Recording Specification. This document is currently in preparation. In the interim, advice is given to waste packagers on a case by case basis. Further information on the requirements for data recording and the strategy being implemented by Nirex can be found in Reference 3.

Identification

The specification for the waste package identification system defines the format of the unique identifier which is to be applied to each waste package destined for the deep repository. The specification also defines the check algorithm which is used to generate 'check digits' which are incorporated within the identifier.

SPECIFICATION DEVELOPMENT

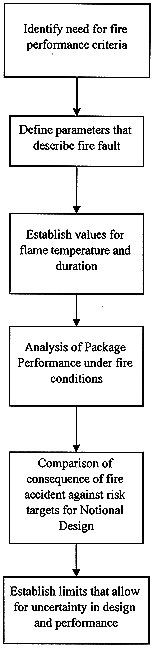

The methodology used to develop waste package specifications is described in the following section, which uses the fire performance criterion as an example. The methodology is illustrated in Figure 1.

Fig. 1. Flowchart illustrating approach to derivation of fire criteria.

Identify need for Fire Criteria

Hazard assessment studies have identified that fires involving waste packages, could be experienced during repository operations via a number fault scenarios, including package transporter electrical fires and pool fires resulting from the use of fuel oils. The inclusion of a fire performance criteria within the specifications is important because it establishes a baseline level of fire performance against which waste package design and repository development can be progressed.

Having identified the need for a particular requirement, the next stage is to derive the most appropriate form for the criterion. In the case of fire performance, fire intensity and duration were identified as being the two key parameters that describe fire severity and affect the release of radioactivity.

Establish Values for Fire Temperature and Duration

Specific values for flame temperature and duration appropriate for a deep underground repository were derived based on published material. Studies by Sandia Laboratories [4] examining the severity of fires in transportation accidents were found to be relevant. Flame temperature is affected by a number of variables, but the dominant one is the fuel itself (i.e. combustible material involved in the fire). Duration, on the other hand, is dependant on non-deterministic factors such as quantity of fuel involved, quantity of flammable and combustible materials and their surface areas, size of pool resulting from accident, probability of fires spreading to the fuel, fire fighting measures and their effectiveness, etc. and can therefore be treated in a probabilistic fashion.

The Nirex methodology was to use a Monte Carlo model to derive a probability distribution of fire duration based on the work reported by Sandia. Factors such as weight of cargo, fraction of cargo that is flammable, and quantities of fuel present in different types of vehicle were assumed to follow Weibull distributions, from which values were chosen randomly and results analysed. The results are shown in Figure 2 which demonstrates that a duration of 30 minutes encompasses 85% of transport related fire accidents. However, for a deep repository in which access and fire fighting capabilities are restricted, a 1 hour fire duration was adopted.

Fig. 2. Cumulative probability distribution for fire duration.

The other aspect of fire severity is flame temperature. Experience from transportation accidents suggests that an all-engulfing fire, of flame temperature 800oC, is an appropriate measure [5]. However, in the case of waste package specifications for the deep repository, studies by Nirex indicated that flame temperature transients of up to, and possibly beyond, 1000oC were possible and given that at some stage of the emplacement process, unshielded packages would have to be removed from the protective shielded transport container, a temperature of 1000oC was adopted. This was recognised as presenting a worst-case but one which would not foreclose design options and which would provide repository operators with the flexibility of using diesel powered vehicles underground. This analysis is consistent with flame temperatures reported for the 1996 Channel Tunnel fire [6]. The next stage was to determine the response of the waste package to such conditions and to identify appropriate release criteria.

Analysis of Package Performance under Fire Conditio

nsNirex has undertaken extensive fire research programmes to investigate fire performance of immobilised ILW and has as a consequence a comprehensive database of fire release fraction data. This has shown that for conventional cemented wasteforms, radioactive releases increase progressively with temperature. Using cemented magnox sludge as an example, the release fraction for caesium-137 has been determined to be 2.3 x 10-4 at 300oC, increasing to 2.5 x 10-1 at 1000oC and the release fraction for plutonium-239, 2.3 x 10-7 at 300oC and 2.4 x 10-6 at 1000oC. As a result of this knowledge, Nirex has developed a methodology which permits the calculation of integrated release for a given waste package temperature distribution. Therefore, given external fire conditions of 1000oC and a duration of 1 hour, Nirex can estimate the activity release from the package for any given initial inventory. Further information on this methodology is given in reference 7.

Comparison of Performance Against Risk Targets

In defining the notional repository design referred to earlier, reasonable assumptions were made with respect to factors such as filtration system efficiency and the extent of particulate deposition within ductwork. The notional design is sufficient therefore to permit estimates to be made with respect to off-site radiological consequences in the event of the fire accident defined previously. The consequences and risk can be compared against radiological protection targets for the repository and an acceptable package release defined.

Establish Limits

For the notional design, releases were found to be well within repository risk targets. Taking into account the need for margins to cater for future design changes and uncertainties with respect to the definition of critical groups, the release limit for a 500 litre drum package was set at 20A2, where A2 is defined in the IAEA Transport Regulations [8]. Although developed for use in transportation safety assessment, the A2 measure is also suited to this type of application since its derivation takes account of significant exposure pathways such as photon dose, inhalation dose, skin and ingestion dose due to contamination transfer and so on.

The performance criterion specified for the 500 litre drum is therefore as follows

The fire criterion is considered to provide flexibility to both package and repository designers and to encompass all credible fires which could be encountered within the generic repository system. The studies conducted into package fire performance have shown that the behaviour is predictable for given conditions and the absence of any cliff edge effect from the wastes investigated further confirms the acceptability of the criterion.

CONFIRMATION OF PACKAGE PERFORMANCE

In the UK there are over 1,000 wastestreams predicted to come forward for deep disposal, a range of possible container designs and several potential encapsulants. Adequate waste package performance can therefore be achieved by a number of means. The strategy adopted in the UK is for waste packagers to develop proposals which are submitted to Nirex for detailed assessment. The waste package specifications are available to the packager as a guide, assisting in the development of packaging concepts which are consistent with the plans for transport and disposal.

When considering a customer's proposal, Nirex will carry out detailed assessments in 15 technical areas, of which fire performance is one (a description of the 15 assessment areas is given in reference 9). In this case, the performance of a specific wasteform and container combination is assessed to determine the response of the waste package to the criteria defined within the specification. In performing the assessment, Nirex will utilise its existing fire performance dataset, in conjunction with thermal modelling if this is needed to generate appropriate temperature profiles through the waste package.

If the package is found to be consistent with the specifications and does not show a major and unacceptable step change in consequences if criteria are exceeded by credible margins, then Nirex can issue a 'Letter of Comfort'. This signifies that the proposed waste package is consistent with current plans for transport and disposal at the repository. If any undesirable characteristics are identified, means for providing mechanisms to limit the consequences are investigated. This process will require a balance to be achieved with respect to the relative implications for repository design and package design.

CONCLUSIONS

In the absence of a finalised repository site, design or associated safety cases, Nirex is not in a position to issue Conditions for Acceptance. Nirex has developed a strategy to facilitate early waste packaging by providing guidance through Waste Package Specifications, supported by the formal assessment of specific packaging proposals on a case by case basis. The Waste Package Specifications are comprehensive and cover all aspects of the waste package including dimensions and other key features, performance requirements, wasteform characteristics, QA and data recording requirements.

The Waste Package Specifications will be subject to periodic review as knowledge of repository design and safety cases improves and confidence increases. The Specifications will progressively become site and design specific, and this is likely to lead to a relaxation in a number of criteria. It is anticipated that the specifications will eventually form the basis for Conditions for Acceptance for the deep repository.

The strategy of conducting rigorous assessment against the requirements of generic specifications has been successfully followed by Nirex and customers for the past 10 years, and has permitted wastes to be packaged for deep disposal, in the absence of a finalised site and safety cases for the repository. Because the process has its basis in a generic repository concept, it remains robust and continues to be an important component of the UK's waste management strategy.

REFERENCES