BLAST FURNACE SLAG CEMENT FOR STABILIZING

RADIOACTIVE AND MIXED WASTES

T. Sasaki, S. Mihara, M. Shibuya

Nuclear Research Center

JGC Corporation, Japan

R. Kobayashi

JGC Corporation

Washington Office

Chantilly, VA

T. Nakashima, Y. Patil, P. Denault

ADTECHS Corporation

Chantilly, VA

ABSTRACT

Blast furnace slag material has a history of use as an additive in Portland cement based mixes to improve the properties of a stabilized waste form. Improved compressive strength, leach and water immersion characteristics are possible when slag material is added to a formulation. Over the past few years, research on the use of slag material based cement has shown encouraging results. This paper summarizes work performed by JGC Corporation, ADTECHS Corporation and Nippon Kayaku Company Ltd. to investigate the solidification/stabilization of various radioactive and mixed waste streams with Alkali Activated Slag Cement (AASC) as the binder.

Beaker and pilot scale tests with concentrated liquid waste and sludges, ion exchange resin, HEPA filters and incinerator ash generated at nuclear power plant and nuclear fuel reprocessing facilities, have confirmed that the AASC binder permits higher waste loading than traditional Portland cement based encapsulation technologies while improving the overall characteristics of the processed waste form and meeting environmental and radiological waste disposal criteria. JGC has named this process the Super Cement (SC) Process.

Blast furnace slag is the main raw ingredient. Initial testing was performed with Japanese material. Follow on tests have confirmed that U.S.A. slag can be used to achieve excellent results even if there exist slight differences in the chemical composition between the two.

INTRODUCTION

Nuclear facilities including power generating stations, fuel reprocessing plants, government laboratories and weapons facilities, radioactive and mixed waste treatment centers and commercial and industrial facilities generate a variety of radioactive and mixed wastes. These waste have a wide range of physical and chemical characteristics which require a number of conditioning and processing technologies to ensure cost effective and environmentally safe disposition. In Japan, many waste streams are encapsulated using cement, asphalt (bitumen) and plastic (polymer)(1) solidification. Such waste streams include:

Recently, Japan has allowed shallow land burial for the low level solidified waste. The safety analyses performed indicate that inorganic binders are more stable than organic binders due to lower probability of radioactive isotope leaching. However, conventional cement technology does not allow the high waste loadings necessary to meet budgetary requirements.

JGC and Nippon Kayaku Co. Ltd. have performed a detailed study to determine the best inorganic solidification technology for these waste streams. Alkali Activated Slag Cement (AASC) was shown to be a superior product when judged on waste loading and leach characteristics. Both bench scale and pilot scale tests were successfully performed.

Super Cement is being proposed for volume reduction and stabilization of HEPA filters prior to disposal. Conventional cement solidification of HEPA filters could generate hydrogen gas after encapsulation due to the reaction of the aluminum spacers with the cement material. The Super Cement process eliminates this problem during the pre-treatment step with the alkali activator. The activator dissolves the aluminum as well as the filter material forming a sludge which is stabilized when the slag material is added.

ADTECHS, a wholly owned U.S. subsidiary of JGC has also been investigating the use of AASC for stabilizing radioactive and mixed wastes. Together, ADTECHS and JGC have performed a series of tests with DOE waste streams to demonstrate the suitability of Super Cement to meet disposal site Waste Acceptance Criteria (WAC) and the Land Disposal Restrictions (LDRs) for characteristic mixed waste streams. The results of these tests are discussed in this paper. In summary, the Super Cement process has successfully stabilized all of the DOE waste streams tested.

JGC has performed a detailed evaluation of slag materials produced by the US and Japanese steel industries. Careful selection of slag materials is a must to obtain the best results. JGC has obtained excellent results with both Japanese and US products.

THE SUPER CEMENT PROCESS

AASC was originally developed by Nippon Kayaku Co. Ltd. for non-nuclear applications. The main ingredient is blast furnace slag. This material does not undergo conventional cement type hydration reactions when contacted with water. However, by raising the pH using the alkali activator, hydration reactions occur resulting in a conventional xCaO-ySiO2-zH2O type matrix (C-S-H) found in hydrated Portland cement. The AASC product is much more dense than the normal Portland cement product and has a higher compressive strength at equivalent waste loadings(2).

JGC, in conjunction with Nippon Kayaku Co. Ltd., has refined AASC for nuclear waste applications. Formulations are developed that meet compressive strength and leach criteria for radioactive and mixed waste disposal both in Japan and the United States. JGC has named the process Super Cement process for nuclear waste applications.

A large number of tests have been performed using simulated waste formulations from nuclear power plants and reprocessing plants. The tests were conducted in beaker scale and pilot scale apparatus; various properties of the solidified material were examined.. The test results for sodium borate, sodium sulfate, sodium nitrate, ion exchange resin, incineration ash and HEPA filters are shown in Table I. The first three simulated wastes were tested in powder form. As a comparison, the conventional cement product characteristics are also listed. These results confirm that the Super Cement process enables high waste loadings to be obtained while maintaining a high compressive strength value and excellent water immersion performance. Table II provides leach indices data (ANS 16.1) for various waste using actual radioisotope tracers.

Table I. Physical Characteristics of Typical Waste Forms

Table II. Leachability (LIX) of Radionuclides in AASC Products

PRETREATMENT AND SUPER CEMENT SOLIDIFICATION FOR LIQUID WASTES

Both boric acid and sodium nitrate wastes are typically generated and stored in a liquid form. In order to take advantage of the superior Super Cement waste loading characteristics and the low water requirements of Super Cement, concentration of the waste through an evaporative process is recommended. For that purpose, JGC has developed a pre-treatment evaporator system, called Super Concentration, which generates a crystalline slurry waste.

The waste is concentrated in a high shear mixer/evaporator. The liquid waste stream is fed directly into the unit and super-concentrated to produce a slurry solution. The Super Cement materials are then added and homogeneously mixed. Figure l shows the pilot plant sized mixer with a capacity to solidify 100 liter batches. By increasing the salt concentration of the waste, the waste loading in the Super Cement waste form also increases. The water requirement for Super Cement is much lower than normal Portland cement which generates a denser product. Figure 2 illustrates an evaporation/solidification pilot scale experiment with a 100 liter drum of simulated sodium borate waste.

Fig. 1. Pilot scale equipment for SC solidification.

Fig. 2. Sodium borate solidification with SC.

The first step in the processing of a borate waste is an adjustment of the sodium and boron molar ratios in the solution to 1. At the end of the evaporation phase, the concentration of sodium borate hydrate (NaBO2 A 4H2O) in the waste form reaches 88wt%. Next, the temperature of the slurry solution is reduced to about 50° C while continuing agitation. At this point, the Super Cement ingredients and additives are mixed into the waste slurry until a homogeneous mix is obtained. After pouring into the drum, the waste is solidified within 20-30hours. A typical waste loading for sodium borate is 60wt%, based on NaBO2 A 4H2O. Good homogeneity in the drummed product was confirmed by coring the drum and measuring the density of the samples.

The same super-concentration technique was used to treat liquid wastes containing sodium sulfate and sodium nitrate. The sodium sulfate salt solubility is about 30wt% in water even at higher temperatures. A 60wt% Na2SO4 slurry is obtained using the super-concentration mixer equipment. Sodium nitrate has a high solubility in water and the super-concentration method generates a NaNO3 solution of more than 80wt%. In both cases, the slurry solution is directly mixed with Super Cement at temperatures in the 40-50° C range to produce the waste form with good homogeneity. The waste loadings for Na2SO4 and NaNO3 in the final waste forms are 30wt% and 60wt%, respectively.

The test program has demonstrated conclusively that super-concentration and Super Cement solidification are effectively carried out in a single piece of equipment to produce a stabilized waste, with high salt content.

ION EXCHANGE RESIN WASTES

The operation of nuclear power stations generates spent ion exchange resins from the purification of the primary coolant and the demineralization of waste waters. A mixture of cation and anion resin is generally used. The solidification of resins requires that the resins are first dewatered prior to the addition of Super Cement materials. A relationship between weight content of the resin and the required water content in the waste form was studied to find the appropriate solidification conditions. Figure 3 illustrates the results. The optimum free water content ranges between 23 and 33 wt%. At this water content, the Super Cement process produces a waste form containing 50-60kg of resins (based on dried weight) in a 200 liter final product volume. There is no free standing water or segregation of anion resins. Fluidity of this mixture is excellent. The results obtained with ion exchange material are independent of the resin type, bead or powder, and the anion to cation ratio(3).

Fig. 3. Formulation range for resins with SC.

INCINERATOR ASH WASTE

An incinerable Dry Active Waste (DAW) is incinerated at nuclear power plant sites in Japan. Ash from the incineration process has been solidified under test conditions using Super Cement. Excellent results have been obtained.

Ash often contains small amounts of aluminum metal. The metal must first be dissolved with an alkali solution to prevent hydrogen generation at the disposal site. This step is combined with the alkali addition step necessary to adjust the pH. The weight of ash waste in the final product is about 130kg in a 200 liter volume. The product has a high compressive strength, about 1700 psi, with 35wt% loading. The product meets the leach criteria for stability and has been demonstrated not to swell upon water immersion.

HOMOGENEOUS CEMENT SOLIDIFICATION OF HEPA FILTER

HEPA filters are normally stored or compacted in a drum in retrievable storage. However, for permanent disposal it will be necessary to encapsulate the filters. Hydrogen gas evolution is anticipated should a cementation process be used to encapsulate the filters.

The application of Super Cement solidification was studied to overcome the problem on the HEPA filter disposal. Since an alkali solution is used to activate the Super Cement, the same alkali solution can be used to dissolve the aluminum metal as a pretreatment. The metal reacts with the alkali solution forming a soluble aluminate or hydroxide. Any hydrogen generated during the reaction can be safely dissipated. Moreover, the glass fiber media in the filter can be dissolved to obtain a slurry with the addition of heat. After the pretreatment, the slurry solution which contains aluminate and dissolved glass fiber is mixed with Super Cement, without neutralizing the excess alkali material. Figure 4 illustrates the pre-treatment and solidification steps. It is calculated that a standard 200 liter drum can hold 8 standard sized HEPA filters after solidification. The issue of hydrogen generation in the disposal site is eliminated.

Fig. 4. Solidification of HEPA filter with SC into a homogeneous waste form.

MIXED WASTE TESTING

Stabilized waste must meet the WAC at the burial site selected for disposal. For most Class A, it is sufficient to show the waste is a free standing monolith. For some Class A and for Class B and C wastes, more rigorous criteria must be met, including a leach test (ANS 16.1). For Mixed wastes, the processor must show that the waste form meets the Land Disposal Restrictions.

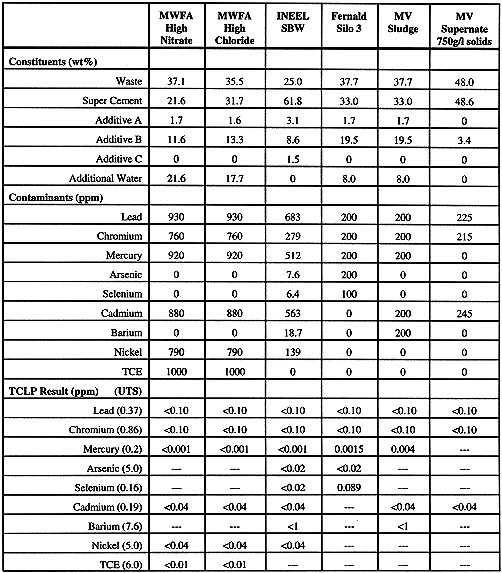

In the United States, the Toxicity Characteristic Leaching Procedure (TCLP) is most often used on treated waste forms to demonstrate the suitability for disposal. In order to verify the effectiveness of Super Cement process, TCLP testing has been conducted for the Melton Valley Tank Waste (sludge), the Fernald Silo 3 waste, the Mixed Waste Focus Area (MWFA) high nitrate and high chloride formulations as well as the Sodium Bearing Waste at the INEEL Chemical Production Facility (CPF). The waste composition for the Melton Valley tank sludge and the Silo 3 material were taken from published reports(4,5). The waste composition for the MWFA and the INEEL wastes were provided by the respective organizations. The stabilized waste formulations and the TCLP results are listed in Table III.

Table III. Mixed Waste Formulations and Test Results

The chemical composition of the surrogate sludge for Melton Valley Tank Waste is shown in Table IV. The simulant is prepared in the following manner. The chemical compounds which are constituents in the waste are provided as a soluble salt such as nitrate salt. The pH was adjusted into the alkaline range. Toxicity metals, defined by the Resource Conservation recovery Act (RCRA) found in the Melton Valley Tank sludge were added to the surrogate waste at a concentration of 200 ppm (Ba, Cd, Cr, Hg, Pb). The waste loading was determined by the product's fluidity or by a pre-determined concentration factor.

Table IV. Chemical Composition of Simulated Melton Valley Tank Sludge (W25-S)

The Melton Valley supernate has an average solids content of 380 g/l (average of 8 tanks). ADTECHS and JGC performed stabilization tests at 550 g/l, 650 g/l and 750 g/l solids. The elevated solid content solutions are equivalent to evaporating the waste and concentrating the solids. The TCLP tests on the stabilized supernate waste forms show that lead, chromium and cadmium levels in the leachate are below detection limits.

The results of other simulated mixed waste TCLP tests are provided in Table III. All results show the RCRA metal concentration in the leachate are below the detection level or below Universal Treatment Standards limits. The test results strongly suggest that the Super Cement process can be successfully used with a wide range of waste streams, including Melton Valley supernate and sludge, Fernald Silo 3, the Sodium Bearing Waste from the Chemical Production facility at INEEL and the MWFA surrogates representing a diverse mix of wastes.

The MWFA waste forms had, in addition to the RCRA metals listed in Table III, trichloroethylene (TCE) in the surrogate waste. A head space analysis was performed for these samples to detect TCE. The TCE concentration was below detection limits.

INFLUENCE OF SLAG MATERIALS ON STABILIZATION

The raw materials used in the test program were of both Japanese and U.S. origin. The blast furnace slag material is a by-product of the iron industry. The fast water quench cooling procedure by which the blast furnace slag is made is the same in most countries, including Japan and U.S.A. However, the chemical constituents of the slag may be different. In addition, the physical characteristics of slag, such as particle size, are variables. The chemical composition and particle size are key factors in determining the final waste form characteristics with Super Cement. Therefore careful selection of the slag material is very important.

The raw material cost greatly depends on the transportation component. Therefore, it is preferable to utilize domestic materials, when available, with the correct chemical and physical characteristics.

The slag components depend very much on the starting ore material. It is widely known that there is a difference among each countries products. In this investigation, Japanese materials and US materials have been compared. Table V provides the chemical constituents in the slag. Solidification test were performed using both countries' products. The test result show that fluidity (pourability) for both materials was virtually the same. One minor difference did appear early in the program; the U.S. product tended to cause weeping when the solidified material was exposed to air. This behavior is not considered significant to the long term stability of the product. The weeping may have been due to the MgO content difference(6). By adjusting the water content at the mixing stage, the weeping effect disappeared. The intercomparison results, Japanese and American materials, are shown in Table VI. Every sample had good fluidity and a dry surface after curing. These test results confirmed that domestic American materials can be used successfully.

Table V. Chemical Content of Blast Furnace Slag

Table VI. Comparison of Sodium Nitrate Product with Different Slag Materials

SUMMARY

ADTECHS and JGC have performed extensive testing of the Alkali Activated Slag Cement technology. The program has demonstrated conclusively that Super Cement successfully stabilizes a wide variety of waste streams generated in the nuclear industry. The stabilized wastes have high waste loadings, typically two to three times that obtained with conventional cement technologies and excellent physical properties including very low leachability of radionuclides and toxicity metals.

JGC has demonstrated that the Super Concentration technology can be used to improve waste loadings from liquid waste streams.

The Super Cement technology can be used to stabilize and volume reduce HEPA filters containing aluminum metal. Gas evolution at the burial or disposal site is eliminated.

ACKNOWLEDGMENT

We thank Nippon Kayaku Co. Ltd., who supplied AASC material for this investigation test and also to Messieurs M.Kiyomoto, K.Ikeda and Y.Karasawa who gave JGC valuable advice.

REFERENCES