TESTING PRETREATMENT AND SOLIDIFICATION AGENTS

FOR INSITU REMEDIATION OF MIXED WASTE IN

UNDERGROUND STORAGE TANKS

Peter Shaw*

Idaho National Engineering Laboratory

Environmental Restoration Technologies Department

Lockheed Martin Idaho Technology Co.

2525 N Fremont

Idaho Falls, Idaho 83415-3710

ABSTRACT

This report describes results from laboratory-scale testing of pretreatment and solidification agents for remediating underground storage tanks particularly ones with high liquids content, tritium and chlorinated hydrocarbons. The V-9 tank at the INEEL is representative of such tanks throughout the DOE system and was the object of these tests. The objective was to stabilize sludge, heterogeneous material, and liquids, and reduce leaching of metals and organics. The agents must be easy to apply and mix and able to absorb large amounts of liquids, particularly water containing a high tritium content, with minimum volume increase. The V-9 tank sludge and liquids both contain trichloroethylene (TCE) typical of dense nonaqueous phase liquids found in many underground waste tanks. Three solidification agents were tested on simulated brine and sludge. Both chemically destructive and adsorptive pretreatment agents were tested for reducing the chlorinated organic content. Potassium permanganate, an oxidizer, and zero valent iron, a reductant, were tested for destruction of TCE. Petroset, diatomaceous earth, soil and zeolite were tested for adsorption and immobilization of TCE. These additives were tested also for their compatibility with the stabilization agents. A combination of stabilization agents were found to be the best for stabilizing high water, briny liquid/sludge. Aquaset IIH reduced metals below TCLP levels while solidifying over 40 wt% water. Most of the pretreatments reduced TCE concentrations, and were compatible with the established stabilization agents: Aquaset IIH and Portland cement. Potassium permanganate was the most effective pretreatment agent reducing the TCE below TCLP limits of 0.5 ppm. Potassium permanganate reduced the set of strength of the Aquaset IIH-Portland mixture by less than 20%. Potassium permanganate's effectiveness for destroying organics and Aquaset IIH's absorption capabilities for use in tanks will be verified in the actual treatability study on V-9 contents.

INTRODUCTION

This report describes laboratory test results on pretreatment and solidification agents suitable for treating tank liquids and sludges. Portland cement (PC), Aquaset IIH, and magnesium potassium phosphate (MKP) were all tested on simulated brine and sludge samples for stabilization potential and reduction of metal leaching. Six pretreatment materials were laboratory tested on TCE containing simulated tank brine for effectiveness in reducing the chlorinated organic content: Petroset, potassium permanganate, diatomaceous earth, zero valent iron, and zeolite. The pretreatment additives were combined with solidification agents to test any adverse affect on the final solidified product.

Tanks containing mixed waste usually have contents removed and treated ex situ. In many tanks the contents cannot be easily removed (i.e., solid caked sludge), and an approved treatment does not exist(tritium-containing PCB wastes). Compared with pumping and treating for remediation of tanks, in situ processes are far less expensive and much safer in terms of worker exposure.

Effectiveness of pretreatment agents was determined by meeting regulatory TCLP limits on TCE saturated brine solutions, 0.5 ppm. Effectiveness of the solidification was determined by absence of free liquids, unconfined compressive strength (UCS) above NRC 60 psi limit and leach resistance of final products below TCLP limits. Results obtained from the bench-scale experiments are expected to be applicable to pretreatment of underground tanks containing chlorinated organics, heavy metals and the stabilization of high-liquid sludges. Pretreatment should reduce the hazards of the solidification process and help achieve lower leach limits.

Like many waste tanks buried at the INEEL and throughout the DOE complex, V-9 tank contains chlorinated organics and toxic metals from decontamination cleaning solutions and residues, various surfactants, oils and greases, sludges, biological wastes, and cleaning or organic liquid extraction materials.1 The tank sludge contains 1.8 wt% trichloroethylene (TCE) and 280 ppm PCB (Aroclor-1260) . The Environmental Protection Agency (EPA) Toxic Characteristics Leaching Procedure (TCLP) toxic metals over aqueous limits are mercury (Hg) and cadmium (Cd).. Tritium and most common mixed fission products are in the tank with the majority of the activity coming from Sr-90. The V-9 tank is a 400-gal stainless steel tank located 14 feet underground is about 80% full. The sludge or tank solids contain about 50-66% water and occupy 150 gal. The liquids above the sludge make up about 75 to 100 gal and are primarily a potassium and sodium chloride brine solution.

DESCRIPTION OF MATERIALS

Both the tank sludge and liquid contaminants were simulated to allow control testing in a nonradioactive atmosphere. The tank liquid simulant was composed of technical grade potassium chloride, sodium chloride, and magnesium sulfate in water making a brine solution. Reagent grade TCE was used as the chlorinated organic and dissolved in the brine near the saturated limit of 1,140 ppm. The sludge simulant was composed of sifted, < 10 mm INEEL soil saturated with the brine solution such that the volume of the sludge and the volume of the overlying liquid are in the 2-1 volume ratio estimated in the tank (200 gal sludge to 100 gal liquid).

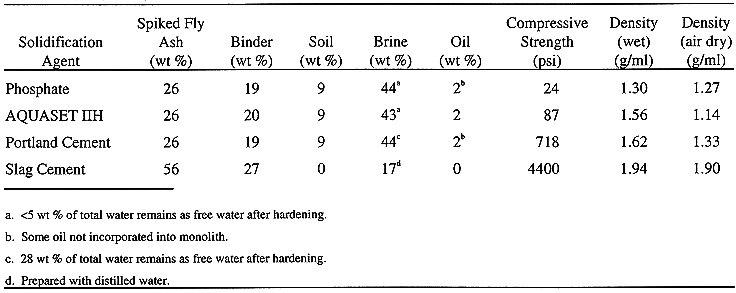

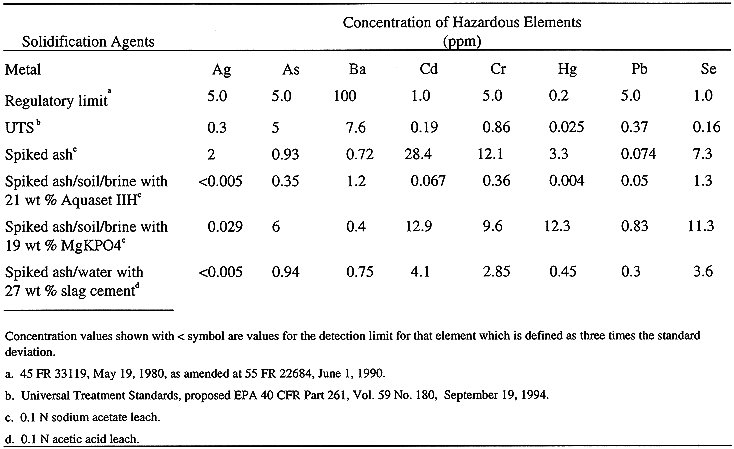

The sludge was spiked by taking a previously prepared spiked ash and adding it to the sludge before solidification. An ASTM class F coal fly ash was spiked with 1 wt% mixed powdered, reagent grade oxides of the eight metals used in TCLP test: silver (Ag2O), arsenic (As2O3), barium (BaO), cadmium (CdO), chromium (K2CrO4), mercury (HgO), lead (PbO), and selenium (SeO2). The ash and oxides were ball milled overnight, separated in containers, and mixed again. This ash was added to the soil to give each TCLP metal a concentrations of about 1000 ppm.Approximate final composition is given in Table 1.

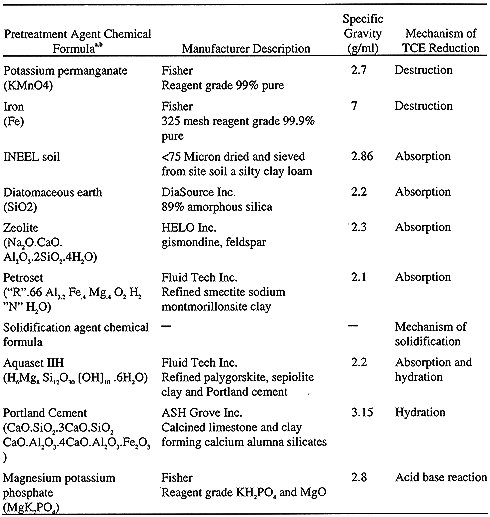

Table I. Description of Pretreatment and Solidification Agents

Six pretreatment agents were tested for TCE absorption or destruction. Chemical destruction is preferred. Absorptive pretreatments prevent the contaminant from leaching but do not alter it The pretreatment agents should: Be able to be added to the tank in dry form and mixed with a shaft paddle, occupy not more than 10% of the volume of the solidification materials, i.e., must work at < 10 wt% concentration and/or have a specific gravity greater than 2, be compatible with solidification materials such as Portland cement, work in a brine solution, React or absorb without heat and additional condition adjustments like pH or ionic strength.

Absorbent-type materials tested were Petroset, zeolite, diatomaceous earth and INEEL soil. Solidification agents themselves also act as organic absorbents. Properties of solidification and pretreatment agents are summarized in Table 1.

Petroset is a proprietary clay-cement based agent marketed by Fluid Tech. Inc. It is nominally a refined Smectite Sodium Montmorillonsite clay ("R".66Al3.2 Mg0.4Fe0.4O2.0 H2."N"H20) with organic absorptive properties. Zeolite is a natural mineral material with a similarity to natural gismodine or feldspar and a tetrahedral structure used primarily for metal absorption.

Diatomaceous earth used here is a white powder mined in Harper Valley, Oregon. The crystalline content is less that 1%. The deposits are the accumulated remains of ocean dwelling plankton called diatoms. The primary species is Melosira. The substance has an oil absorptive capability of 140% and a water absorption of 184%. The INEEL soil is a silty loam with 45% clay and about 30% silicon content. A certain amount of INEEL soil is assumed to be part of the V-9 tank sludge solids.

Potassium permanganate is a medium strength oxidant that oxidizes certain organics with the general reaction, KMnO4 + RCl = MnO2 + KCl + CO2. Permanganate has been used successfully in situ to reduce TCE concentrations to soil.3 Powdered iron reacts reductively, Fe + 2RCl = FeCl2 + 2R. It has been used in situ in reactive barrier walls.4 A catalyst can be used to increase the reaction rate and degree of completion such as the case of palladized iron.5 Compatibility of the pretreatment with the stabilization material is necessary to ensure successful stabilization when applied to tanks containing organics and sludge such as those found in the V-9 tank. The stabilization and pretreatment agents used in the laboratory program are described next.

Successful solidification of tank waste requires material that can be added easily to the tank contents in a concentrated (dry solid) form. Materials can either react with the water with hydration reactions like PC or absorb water and physically remove it as Aquaset II does.. All agents tend to lose strength with water addition. In this case, since the tank will be disposed of or moved as a single unit, the 60 psi required by the Nuclear Regulatory Commission (NRC) for solid low-level waste is used only as a guideline of a reasonable strength desired.

The solidification agents selected : could be added dry, and mixed with extended shaft driven paddles, had specific gravities greater than 2 so they would occupy less than 20% of the volume of the waste material, are compatible with pretreatment materials like permanganate. can solidify a brine solution and react or absorb turning to a solid without excessive heat with no additional adjustments like pH.

Aquaset IIH is a proprietary clay-cement-based agent marketed by Fluid Tech. Inc. It is nominally a refined Palygorskite, Sepiolite clay (H6Mg8Si12O30 [OH]10.H20) with metal fixative as well as absorptive properties. PC type I-II is the standard used in the industry, a calcium alumna silicate. Water hydration forms complex silicates. The phosphate solidification agents were formulated from the reaction of potassium bi-phosphate and magnesium oxide. The solids are mixed and water from the waste initiates the reaction. The magnesium potassium phosphate (MgKPO4,MKP) cement made is similar in structure to natural monazite.

EXPERIMENTAL PROCEDURES

The laboratory program tested solidification agents for stabilization of simulated tank liquid and sludge. TCLP reduction of leaching for TCE and eight EPA toxic metals from stabilized simulated V-9 tank liquid and sludge. Pretreatment agents were tested for removal of TCE from V-9 tank liquids and their influence on solidification agents.

Three solidification agents were mixed with a simulated brine liquid and soil/sludge, allowed to set, and strength tested. Pretreatment agents were mixed with brine containing TCE and tested for their effectiveness in reducing TCE concentrations in the simulant. After the final TCE measurements were taken, the samples were then mixed with Aquaset II and PC to test the effect of the pretreatment agents on the primary solidification material candidates. Spiked sludge samples and TCE containing brines were mixed with stabilization agents and TCLP tested for reduction of leaching.

Control samples were used throughout to track reductions in leaching unrelated to pretreatment and solidification agents used. In the organic experiments, they consisted of a TCE-saturated brine solution with no pretreatment agent to track TCE losses unrelated to pretreatment agents such as volatilization, adhesion to containers. In the TCLP test, reductions in metal leaching from the base material ash and soil were determined by leaching spiked sludge samples with no stabilization material.

Standard analytical procedures, EPA-TCLP-1371 and ASTM-C39 for UCS measurements were used with some modifications to allow for smaller sample sizes, constraints of time, the limited amount of chlorinated organics permitted in the labs and safety considerations necessary for working with TCE.

The test activities described below are, Reduction of TCE Concentration in Brine Matrix, Unconfined Compressive Strength Testing and TCLP Leach Tests

Reduction of TCE Concentration in Brine Matrix

Tests of the effectiveness of various pretreatment agents for reducing TCE concentration were conducted in glass bottles containing spiked brine and the pretreatment agent. 0.1-10 g of each pretreatment agent were weighed into separate 40 mL glass bottles. The TCE containing brine was pipetted into each bottle. Sufficient brine was pipetted so each vial had < 1% free headspace. A teflon stir bar was placed in each bottle except for those containing the metallic iron. All vials were capped with rubber stoppers.

Each pretreatment agent/brine mixture was mechanically mixed by magnetic stirring or shaken (in the case of metallic Fe) in 40-mL vials. Samples are agitated for a week at room temperature and sampled twice. Room temperature during mixing was maintained by the flow of air through the hoods though no appreciable heat generation was detected. After allowing samples to settle 1-2 mL of the liquid was sampled and submitted for organic gas chromatography (GC) flame ionization detection (FID) analyses. The control with no pretreatment additive was analyzed each time. The control accounted for TCE losses to headspace, absorption on the septum, and through the septum. These were appreciable but constant. For this reason, all destruction efficiencies are based on decreases from the control.

Unconfined Compressive Strength

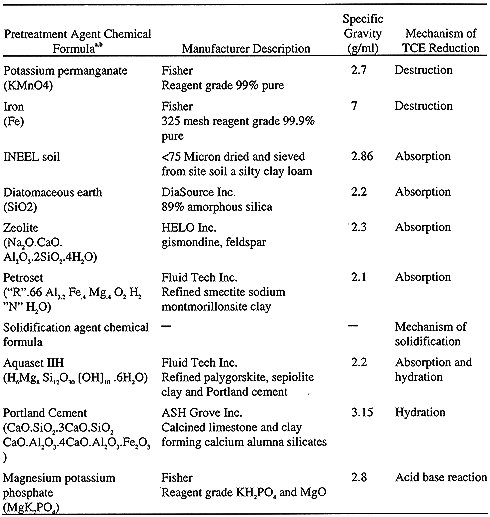

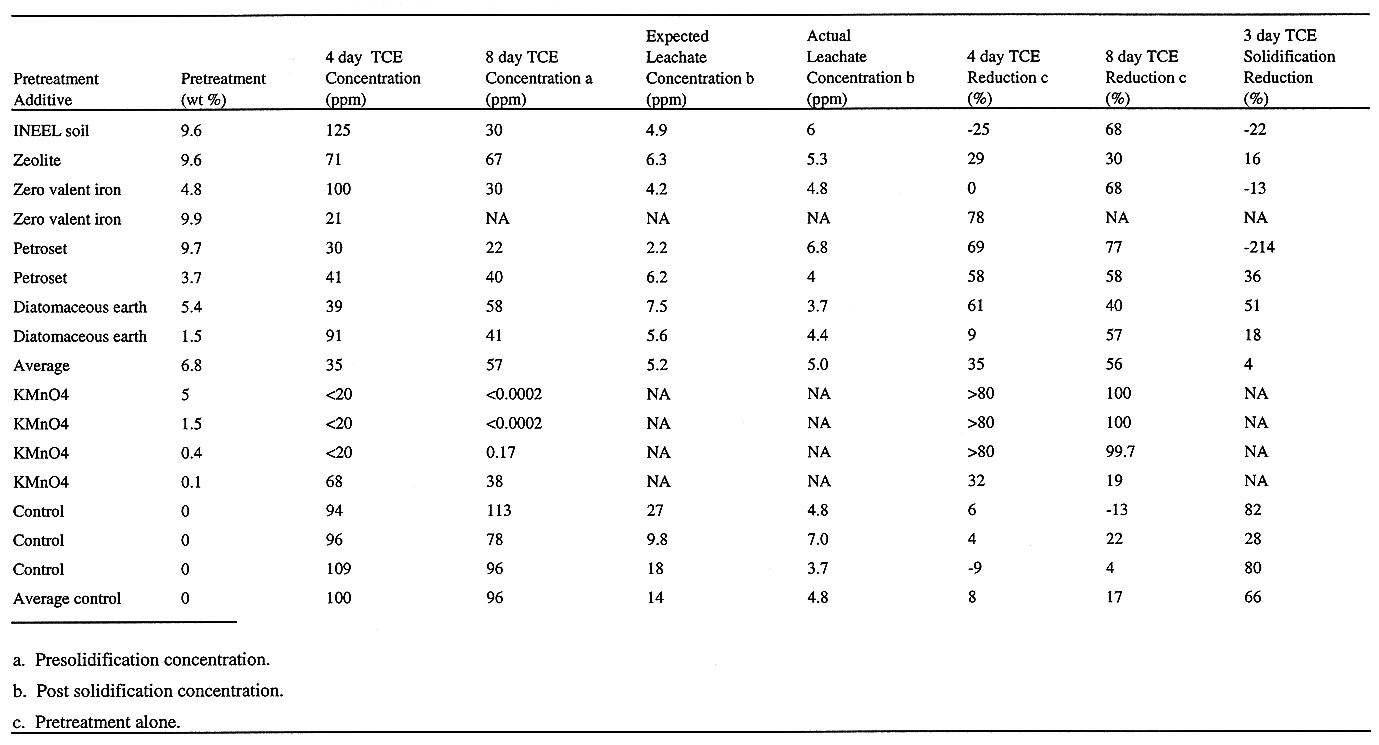

The UCS provides a measure of the binding strength of the solidification agent to the waste and a quantitative determination of durability. The binding properties of Aquaset IIH, Portland, magnesium phosphate waste encapsulation material are affected by pretreatment agents, various brine/sludge/binder ratios, the type of waste (brine vs. tap water), and concentration of liquid. Lowering of the UCS whether from pretreatment agent or waste loading indicates possible diminished durability of waste form. Thus, most of the V-9 liquid pretreatment solutions listed in Table 2 were solidified. The specific contributions of permanganate to UCS are listed in Table 3. UCS and density values are summarized with various solidifcation agents and pretreatments at a variety of waste loadings in Table 3, 4.

Table II. Pretreated and Solidified TCE Leachate Concentrations

Table III. Composition and Physical Characteristics of Soil/ash/brine

Pretreatment

Agent Containing Wasteforms

Table IV. Composition and Physical Characteristics of Soil/ash/brine Wasteforms

UCS was done in accordance with the specifications of the compressibility measurement apparatus (10,000 lb. ECS Versa Loader) and ASTM C39 91. Modifications were made for the small sample size and low strength. UCS is measured by slowly compressing the cylindrical samples 0.05 inches/min. Pounds force is read on a digital strain gauge that has been factory calibrated. Typically the pounds force rises gradually to a maximum, then falls off rapidly when the sample cracks. Irregularities of the sample in shape, presence of voids and general low strength from softness at high waste loadings can lead to multiple peaks (or a very broad peak). This generally results in a lower overall UCS reading. The ASTM test is designed for hard, regularly shaped right cylinders, with the brittleness of cement, with UCS above 500 psi.

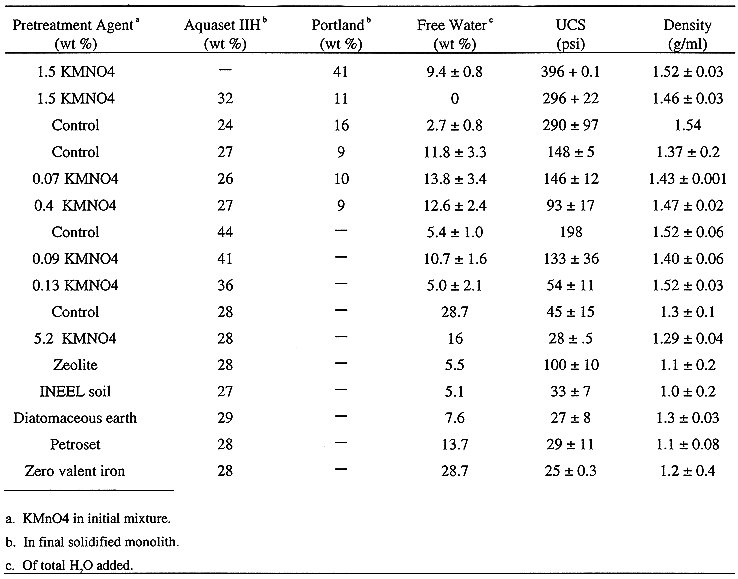

TCLP

The EPA-TCLP leach test used determines the characteristic of toxicity for metals and organics based on a one day leach of small <10 mm fragments. A spiked metal soil/ash mixture was used as a surrogate to test Aquaset IIH fixation of metals in sludge. The composition of the sludge as prepared was listed in Table 4 and 5. Liquid brine was spiked with TCE to determine pretreatment agents affect on organics. In this case spiked liquid samples were first stirred and tested for destruction or absorption of TCE. Those samples above the limit (0.5 ppm for TCE) were then solidified and leached in a standard TCLP leachate again to determine if the pretreatment and the solidifying agent acting together can reduce leaching of organics below regulatory limits.

Table V. TCLP Leaching of Spiked soil/ash/brine Simulated V-9 Wasteforms

TCLP tests were run after the waste mixtures had cured and the density and UCS were determined. The TCLP test for metals was done at a certified lab. The TCLP test for the TCE was modified somewhat using a smaller volume of liquid in the 20:1 mass ration with the small monoliths. Sludge samples were leached for toxic metals after Portland, phosphate, and Aquaset IIH solidification. Pretreatment samples were solidified with Portland and Aquaset IIH and TCLP tested for inhibition of TCE leaching.

RESULTS

Results are described below. Effectiveness is discussed in terms of reducing metals and TCE concentration in leachate and in the final strength of the solidified waste form. Permanganate pretreatment and Aquaset IIH solidification reduced TCE and metals below regulatory limits while giving a free standing waste form with no free liquids.

Pretreatment Agent TCE Reduction

All of the pretreatment materials decreased the aqueous TCE concentration beyond the losses observed in the control. The absorptive agents were about 30-70% effective at the 100 ppm level decreasing concentration to 30-70 ppm. The chemically reactive agents did better than the absorbents. Table 2 lists TCE leachate concentrations both after pretreating and then solidifying as depicted in Figure 1.

Fig. 1. TCE reduction in simulated V-9 tank brine after pretreatment.

KMnO4 pretreatment is the only pretreatment agent tested that brought concentrations low enough to pass TCLP concentrations (0.5 ppm) and reduced them below the detection limit 0.02 ppm. The zero valent iron achieved a 79% reduction. The permanganate reacted more rapidly and completely then the metallic iron, which reacted very slowly over 8 days. The oxidation of organic reaction gives a brown color from manganese dioxide that was noticed within a few hours of agitation. The minimum concentration of permanganate needed to reduce TCE was determined by trying a series of concentrations from 5 wt% to 0.07% in the liquid brine. Permanganate seems to react stoichiometrically with TCE at 1-to-1 mole ratio.

Most of the solidification agents decreased TCE leaching beyond the pretreatment affect. Table 5 indicates that these reductions were most noticeable when starting concentrations were above 50 ppm. The solidification of the unpretreated controls was 70-80% effective at the 100 ppm level, decreasing concentration to 20-30 ppm. These reductions of control samples by solidification agents indicate that these agents act in a similar fashion as the absorbents and were slightly better than some absorptive agents acting alone. No absorbent product or solidification agent can meet TCLP limits of 0.5 ppm, however. When concentrations are below 20 ppm, the solidification agent does not enhance the absorbent effect noticeably, and in some cases the solidification seemed to increase TCE concentration, perhaps releasing it from absorbed material.

Solidification Agent, Density, & Unconfined Compressive Strength

Both the brine alone (discussed above with pretreatment agents) and a sludge brine mixture were solidified. The strength of most agents is typically proportional to the ratio of water to PC (W/C). The W/C ratio in typical construction mixtures varies from 0.5 to 1.5. A ratio of 0.4 is the theoretical stoichiometric amount of water to totally hydrate the PC, but the mixture is not workable.

Aquaset II is exclusively an absorbent agent with no PC and thus little strength. Aquaset IIH, the agent used here, has at least 30% PC making a freestanding product. Increased water loadings generally results in loss of strength as shown in Figure 2. UCS was in general very low (below the 60 psi benchmark value) due to the high water loading (water/Aquaset of 2.3) in this worst-case solidification. In all cases at this loading free water was observed. The UCS generally exceeded the NRC minimum strength criteria (60 psi) for radioactive waste at the expected waste loading.

Fig. 2. Strength of Aquaset IIH solidified simulated V-9 tank brine samples after various pretreatments.

Each solidification agent can handle a certain amount of water before free water is noted. Some of water is chemically combined (waters of hydration) and the remaining is absorbed. The elimination of free water in high water situations generally is proportional to the amount of absorbent like Aquaset IIH, and UCS follows the amount of binder such as PC. Absorbed, chemically uncombined water affects UCS by decreasing the bonding in the internal waste structure. The total water to cement (PC, MKP, Aquaset IIH) ratio has a much greater effect on strength then any other factor.

About 30 wt% of Aquaset IIH is needed to remove free water and obtain a UCS above 60 psi. Table 6 lists the wt % free water remaining after solidifying brine samples. For non-PC-based MKP, salinity seems to also have a strong detrimental effect on UCS. where the UCS of Aquaset IIH and MKP are similar and well below that of PC. Both MKP and PC samples have free water remaining at high water loadings.

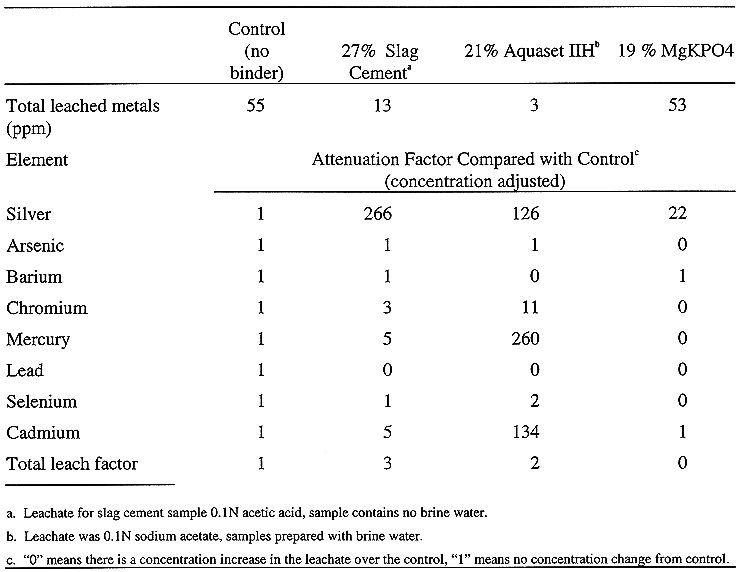

TCLP Test Results

Separate TCLP tests were performed for TCE spiked samples and toxic metal spiked samples. Each waste isolation material caused a decrease in metal leaching over control (spiked sludge with no agent). The concentration of metals after TCLP testing on spiked/solidified sludge samples is shown in Table 5 and Figure 3. The relative effectiveness of each agent in tying up TCLP metals (Figure 4) in solidified samples are shown in Table 6. Aquaset IIH was the best solidification agent for reducing leaching of the eight TCLP metals compared to Portland cement and phosphate cement. Only arsenic concentrations were not decreased from the control. The Aquaset IIH solidification agent in this case has some bonding capacity for most metals based on the observation that the samples do not retain shape upon leaching.

Fig. 3. Toxic metal leachate concentrations with various binders.

Fig. 4. Reduction of toxic metal leaching with various binders.

Table VI. TCLP Metals Attenuation Factors

The Aquaset IIH did little to enhance pretreatment absorption by further tying up TCE in TCE specific TCLP tests. It was effective in absorbing TCE in the control samples as shown in Table II. In most cases, the waste isolation material caused a further decrease in TCE concentration beyond what occurred with the pretreatment agent alone before Aquaset II-H was added. These results are adjusted for dilution and compared with what was expected if the agent had no effect.

Most of the controls that had higher initial TCE experienced a greater percentage reduction than samples made from pretreated material. The Aquaset IIH solidification agent in this case has some absorption capacity for TCE at the higher concentrations of the unpretreated controls. A few pretreated samples had increased concentrations after solidification indicating the solidification agent may have released the TCE absorbed on the pretreatment solid. Thus most of the TCE reduction will occur due to the pretreatment.

TCLP testing for TCE was not necessary on the permanganate treated samples as the limit of 0.5 ppm had already been met. Only permanganate concentrations below the stoichiometric concentration of TCE did not decrease TCE below limits in final leach solution. Generally, the UCS decreased with increasing permanganate concentration.

CONCLUSIONS

Aquaset IIH was an effective solidification agent for absorbing large quantities of liquid including oils while producing a solid that generally had UCS > 60 psi and left no free water or oil layer. It reduced toxic metal leaching below TCLP limits, better than MKP or PC. Solidifying large quantities of water (two times the weight of water to Aquaset) decreased final strengths below 60 psi. Portland gives higher strength mixtures but may not incorporate up to 28% water.

KMnO4 pretreatment was effective in reducing TCE concentration below TCLP limit of 0.5 ppm. Permanganate seemed to react on a 1-to-1 stoichiometric basis with the TCE. Complete reactions took several days for concentrations near this stoichiometric concentration. The reaction starts immediately upon mixing and at 5% has destroyed TCE below limits in several hours. Decrease in UCS is generally proportional to permanganate concentration. An 80% decrease in UCS was observed when 5 wt% permanganate in liquid was solidified.

Qualitatively, the pretreatment additives (except zeolite) do not change mixing or the set of solidification agents but do lower the strength. Most pretreatment agents decreased the UCS of the solidification agents, but usually about 70% of the UCS was retained. Enhancement of solidification by the zeolite could be observed in the uniformity of mixing and greater strength of the formed monolith. The permanganate and Aquaset IIH should be tested in the actual treatability study. Regulatory leachate and strength requirements should be achievable.

REFERENCES

*Prepared for the U.S. Department of Energy Under Assistant Secretary for Environmental Management DOE Idaho Operations Office Contract DE-AC07-94ID013223