RADIOLOGICAL HEALTH IMPACTS ASSOCIATED WITH THE

TREATMENT OF PLUTONIUM RESIDUAL MATERIAL

AT DOE FACILITIES

Gilbert H. Waldman

Science Applications International Corporation

ABSTRACT

During the Cold War, the Department of Energy (DOE) conducted various industrial activities associated with the production of materials for use in nuclear weapons. Several intermediate products and wastes were produced as a result of those operations, some of which are still in storage at various DOE sites. Now that the Cold War is over and the United States has ceased production of weapons materials, DOE is conducting activities to safely manage those intermediate products and wastes. Among the products and wastes requiring proper management are plutonium residues and scrub alloy currently stored at the Rocky Flats Environmental Technology Site (Rocky Flats) near Golden, Colorado. This paper addresses the potential radiological human health impacts (cancer risks) associated with the various treatment methods available for managing these residues and scrub alloy.

Health impact discussions are geared toward the examination of several material categories (e.g., ash, salts, sludges). The management of these materials requires individual processes which may involve a number of chemical, thermal, or physical applications. These industrial applications are essentially geared toward supporting any of the following alternatives: (1) continued stabilization of materials for interim storage at Rocky Flats, (2) further on-site treatment at Rocky Flats to prepare for disposal at the Waste Isolation Pilot Plant (WIPP) or other disposition, and (3) further off-site treatment to prepare for disposal at WIPP or other disposition.

This paper specifically focuses attention upon the potential radiological impacts that may be incurred to a maximally exposed member of the public, as well as entire population groups which reside in close proximity to designated processing facilities. Radiological impacts to workers involved with processing activities are also examined. The scope of these discussions is oriented toward impacts associated with "incident-free" (i.e., normal) operations.

INTRODUCTION

Plutonium residues and scrub alloy were generated during recovery and purification of plutonium and manufacturing of components for nuclear weapons. Approximately 125,000 kilograms of residues (containing about 5,800 kilograms of plutonium) and approximately 700 kilograms of scrub alloy (containing about 200 kilograms of plutonium) are currently stored at various DOE sites. The vast majority (~85% by weight) of this residual material and scrub alloy is located at Rocky Flats; the remaining 15% can be found at the Savannah River Site (SRS), Hanford Site, Los Alamos National Laboratory (LANL), and Lawrence Livermore National Laboratory.

In order to facilitate needed processing or other disposition of the residues and scrub alloy at Rocky Flats, a National Environmental Policy Act (NEPA) analysisa was performed in 1997 in support to the Department of Energy’s Office of Nuclear Material and Facility Stabilization. A key focus of this analysis was placed upon potential human health impacts associated with a number of material processing alternatives that could be conducted at Rocky Flats, SRS, or LANL. The main objective of this paper is to therefore present, compare, and discuss the calculated radiological health effects that are associated with these process alternatives.

RESIDUE CATEGORIZATION

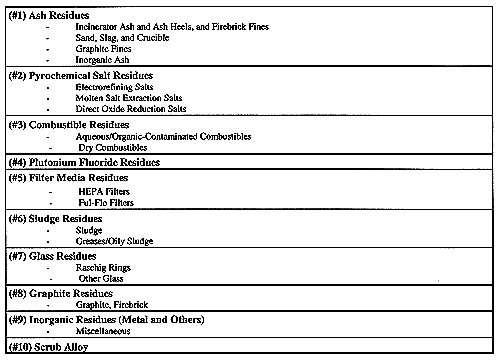

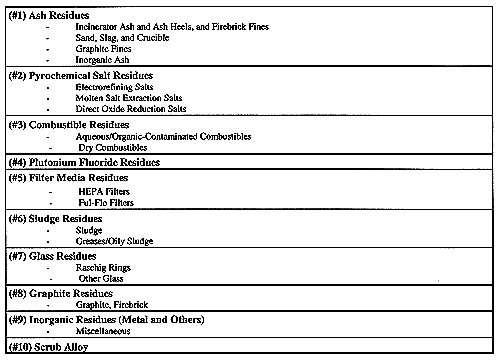

For the purpose of calculating impacts, the Rocky Flats plutonium residues and scrub alloy were grouped into categories that require similar processing technologies; the categories are as follows:

These categories were then broken up into applicable subcategories, as they realistically apply to the existing quantities of residues and scrub alloy at Rocky Flats. Table I provides a breakdown of these subcategories.

Table I. Categories and Subcategories of Residues Evaluated for

Radiological Impacts

The plutonium residues and scrub alloy processing technologies evaluated were identified through a process that included review of technical reports and evaluation by technical experts from DOE Headquarters, Rocky Flats, the Savannah River Site, and Los Alamos National Laboratory. These experts also evaluated the feasibility of implementing the technologies at the DOE sites under consideration. The following is a listing of all processing options that were analyzed for potential human health impacts, and the sites at which they could be performed:

IMPACT ASSESSMENTS

Processing of the Rocky Flats plutonium residues and scrub alloy at Rocky Flats would be done primarily in two buildings at the site, Building 371 and Building 707. Building 371 would be used for processes that involve aqueous processing steps including mediated electrochemical oxidation, neutralization, sonic wash, cementation, acid dissolution, water leach, catalytic chemical oxidation, thermal desorption/steam passivation, and some blend down, cementing, and repackaging operations. Building 707 would be used for processes that are primarily thermal or physical operations including immobilization, pyro-oxidation, calcination, salt distillation, and some blend down and repackaging operations.

Several processes that involve separating plutonium were analyzed for SRS and LANL. These sites have unique facilities and/or processing expertise for separating plutonium from certain categories of plutonium residues and scrub alloy that are not available at Rocky Flats. If SRS and/or LANL are subsequently utilized, material from Rocky Flats would undergo shipment to these sites.

The Savannah River Site facilities for the separation of plutonium include the H-Canyon, HB-Line, F-Canyon, and the FB-Line. Use of these facilities, some of which are designed for remote operation, would result in lower worker radiation exposure than use of the glovebox facilities at Rocky Flats. For example, plutonium fluorides have an extremely high worker radiation dose due to the (a ,n) reactions between the alpha particles in plutonium and the fluorine molecules. The plutonium separation process at Savannah River Site (Purex) is performed in a remote-handling facility, which reduces worker dose substantially. Sand, slag, and crucible has significant amounts of americium (Am), which promotes a much higher worker radiation dose than plutonium does (due to g -radiation emitted from Am-241). The plutonium separation process for sand, slag, and crucible (Purex) is also performed in a remote-handling facility at SRS. Many of the pyrochemical salts also contain significant amounts of americium. Although the separation technologies for salts to be processed at Los Alamos National Laboratory (distillation, water leach) are not remote-handled, they consist of much shorter time exposures to the salts than the non-separation technology (blend-down) does, thereby reducing worker exposure substantially. Furthermore, the separation technologies result in a smaller quantity of processed material requiring handling at the processing sites than those processes that stabilize the residues and scrub alloy through immobilization or blend down of those materials through the addition of inert or low plutonium content materials. This further reduces worker exposure and generates less transuranic waste requiring disposal at WIPP.

As stated, LANL is considered as a candidate site for two separation process technologies. Scientists at Los Alamos National Laboratory developed the salt distillation technology being considered for separation of plutonium oxide from certain pyrochemical salts. LANL is also being considered for water leach of direct oxide reduction salts. Any processing activities at the site would be done in Building PF-4, at TA-55, the LANL Plutonium Facility.

At this juncture, a summary of incident-freeb radiological impacts (to members of the public and involved workers) is presented to serve as a "stepping stone" into subsequent discussions of how and why these impacts (i.e., cancer risks that result from radiological doses) differ amongst each other from process to process and from site to site. Illustrative examples of how worker impacts can vary have already been touched upon in the preceding paragraphs; in later discussions, similar scenarios shall be presented and interpreted (for both public and workers) in regard to what significance these differences could potentially have.

Through the use of The Hanford Environmental Radiation Dosimetry Software System (the GENII Computer Code), potential radiological doses to members of the public from incident-freeb processing operations were determined (i.e., modeled) over the lifetime of the each process. GENII calculates these public doses by using such site-dependent factors as meteorology, population distributions, agricultural production, release quantities, stack heights, and minimum site boundary distances. For example, to calculate an "inhalation" dose (from a plutonium release) to an individual located at a given site boundary, GENII would utilize the following equation in its calculation:

Inhalation Dose (mrem) = (c /Q)· (Inhalation Dose Conversion Factor)· (Release Quantity)· (Breathing rate)

whereby: c /Q = Atmospheric Dispersion Coefficient (sec/m3); which the code tabulates via meteorological data input

Inhalation Dose Conversion Factor (mrem/Ci); which is the established empirical dose per unit release

Release Quantity (Ci); the actual activity of airborne plutonium released from a facility

Breathing Rate (m3/sec); the volumetric rate at which air is respired by the average adult

Doses to involved workforces (i.e., "processing" workers) were estimated over the lifetime of each process using site-supplied information which places emphasis on historical experience with similar operations. From these public and worker doses, associated risks of incurring a latent fatal cancer were then calculated using estimators established by The International Commission on Radiological Protection and the 5th Committee of the Biological Effects of Ionizing Radiation (BEIR V). These estimators are 500 excess fatal cancers per million person-rem for the public, and 400 excess fatal cancers per million person-rem for the involved workforce. The value for the workforce is lower due to the absence of children in this group.

Table II presents the calculated radiological health risks associated with each possible processing option pursuant to this analysis. Four different cohorts are presented in a parallel fashion for each residue subcategory; these cohorts are: (1) a maximally exposed member of the public (MEI), (2) a public population living within 50 miles of the release point, (3) a maximally exposed involved process worker, and (4) an involved worker population.

Table II. Radiological Impacts of Managing Rocky Flats Plutonium Residues

and Scrub Alloy at Rocky Flats, SRS, and LANL

INTERPRETATIONS

As previously stated, impacts to the public were modeled via the use of the GENII computer code. The estimated release quantities (i.e., source terms) associated with the majority of modeling scenarios were assumed to be representative of the Weapons-Grade plutonium that exists in the residues and scrub alloy; hence, the following "unit" (i.e., activity per unit mass of weapons-grade Pu mix) source term spectra was employed:

Plutonium-238: 0.0050 Ci/gram of WG-Pu

Plutonium-239: 0.0576 Ci/gram of WG-Pu

Plutonium-240: 0.0129 Ci/gram of WG-Pu

Plutonium-241: 0.3360 Ci/gram of WG-Pu

Plutonium-242: 0.0000012 Ci/gram of WG-Pu

Americium-241: 0.00060 Ci/gram of WG-Pu

On a per-isotope basis, for most processing options, it was found that Pu-239 was the main dose contributor to both the MEI and the general population living within 50 miles of Rocky Flats; this is not surprising given the fact that Pu-239 has a very large inhalation dose conversion factor, and that the release quantities of Am-241 are minimal for the majority of processing options at the site. Overall public impacts at SRS and LANL were found to be similar in quantity as those calculated for Rocky Flats; however, due to larger Am-241 releases associated with certain processes at these sites (i.e., SRS and LANL), a proportionally larger dose from this isotope is expected than from Pu-239, for these cases. From a scientific perspective, these are noteworthy items; however, it is pertinent to realize that from a "realistic" point of view, all of the public doses (and associated cancer risks) are extremely small. The processing doses are several orders of magnitude smaller than what one incurs from natural background radiation in a single day. Similarly, the public risk of incurring latent fatal cancer from any of these processes is millions of times less than the lifetime risk of dying in an automobile accident. The primary reason for these "microscopic" public impacts is due to the extremely small release quantities that are expected for each of the processes. For example, the average release quantity for a process at Rocky Flats is expected to be on the order of 10-7 grams over the lifetime of the process. These extremely small release amounts are primarily attributable to state-of-the-art filtration systems that are expected to reduce emissions by several orders of magnitude. In regard to regulatory compliance, all of the processing actions analyzed would not cause any of the sites to violate EPA’s Clean Air Act (40 CFR 61) limit of 10 mrem/yr to an individual. Since there are no releases expected to liquid pathways from these processes, compliance with EPA’s Safe Drinking Water Act limit of 4 mrem/yr is not applicable.

We shall now briefly discuss the ranges of public and worker impacts associated with each site’s process activities. At Rocky Flats, the probability of a latent cancer fatality ranged from 1.0x10-13 (Vitrification of Glass) to 2.2x10-10 (Pyro-Oxidation and Water Leach of Electrorefining and Molten Salt Extraction Salts) to a MEI located at the Rocky Flats site boundary. The number of latent fatal cancers amongst the population surrounding Rocky Flats (within 50 miles) ranged from 4.3x10-9 to 5.0x10-6 for the same processes cited for the MEI, respectively. A key reason for the "3-order" difference in these impacts is attributable to an extra quantity of Am-241 that is characteristically released in the Pyro-Oxidation/Water Leach processing of salts. This extra Am-241 release is in fact inherent to all salt processing options that may occur at either Rocky Flats or LANL. As a result, it is readily evident that the salt processing public impacts are consistently higher when compared to public impacts for most other residue materials. In addition, cumulative quantities of released particulates may vary quite significantly amongst the different processing options. For a maximally exposed individual worker, the probability of a latent fatal cancer was conservatively equated to that associated with the DOE Administrative Control Level dose of 2,000 mrem/yr (i.e., 0.0008 risk), across the board for all processing options. The number of expected latent fatal cancers within the worker population however varied to a large extent amongst the processing options at Rocky Flats. This range was marked by 0.0004 (Vitrification of Glass) to 0.29 (Pyro-Oxidation and Blend Down of Electrorefining and Molten Salt Extraction Salts). Once again, the primary reason for the significantly higher value(s) of the salt process(es) is because of increased worker g -exposure from Am-241. As an additional note, the "anomalous-looking" 0.142 latent fatal cancers to the workforce associated with the Blend Down of Plutonium Fluorides, stands out for a reason; as mentioned in the introductory section of this paper, there is an (a ,n) reaction that occurs between the plutonium and the fluorine. As a result, the workers are subjected to a neutron dose in addition to the g - dose they may receive from Am-241 or the plutonium isotopes. Process workers at Rocky Flats are not expected to receive any dose from a radiation due to all process operations being conducted via gloveboxes or other protective system. Workers may receive small doses of b -radiation (to the hands) as a result of the decay of Pu-241, while working in gloveboxes.

At SRS, the probability of a latent cancer fatality ranged from 1.0x10-11 (MEO/Purex of Inorganics) to 7.5x10-10 (Purex of Incinerator Ash) to a MEI located at the SRS site boundary. The number of latent fatal cancers amongst the population surrounding SRS (within 50 miles) ranged from 1.2x10-6 to 8.5x10-5 for the same processes cited for the MEI, respectively. As is evident by this range, there is less breadth in the estimated public impacts at SRS amongst the applicable processes, than at Rocky Flats. The primary reason for this is due to the similar types (and limited number) of processing options available at SRS (only Purex or MEO/Purex); hence, release quantities amongst the processed materials are relatively consistent and therefore so are the associated public impacts. For a maximally exposed individual worker, the probability of a latent fatal cancer was conservatively equated to that associated with the DOE Administrative Control Level dose of 2,000 mrem/yr (i.e., 0.0008 risk), across the board for all material processing options. The number of expected latent fatal cancers within the worker population however varied to a noteworthy extent amongst the processing options at SRS. This variance is not necessarily attributable to significant differences in worker exposure rates during hands-on operations, but rather as a result of certain processing options lasting for longer durations than others, thus producing larger "cumulative" workforce doses. This range was marked by 0.0018 (MEO/Purex of Inorganics) to 0.092 (Purex of Incinerator Ash). As was stated earlier, it should be noted that in a number of cases (such as with Sand, Slag, and Crucible), the remote handling characteristics of Purex processing at SRS can reduce potential worker exposures (which would otherwise be received at Rocky Flats) by a considerable extent. Just as at Rocky Flats, process workers would be expected to receive primarily g -doses from Am-241, and a small neutron dose from working with the Plutonium Fluoride residues.

At LANL, the only materials that fall under processing options are Electrorefining/Molten Salt Extraction salts, and Direct Oxide Reduction salts. The probability of a latent cancer fatality ranged from 4.2x10-11 (Water Leach of Direct Oxide Reduction salts) to 1.2x10-10 (Salt Distillation of Electrorefining/Molten Salt Extraction Salts) to a MEI. The number of latent fatal cancers amongst the population surrounding LANL (within 50 miles) ranged from 1.2x10-7 to 3.6x10-7 for the same processes cited for the MEI, respectively. As is evident by this range, there is less breadth in the estimated public impacts at LANL amongst the applicable processes, than at Rocky Flats. The primary reason for this is due to the limited number of processing options available at LANL (only Distillation and Water Leach) and the consistent use of the same facility (i.e., same filtration reduction factors) for both options; hence, release quantities amongst the processed materials are relatively consistent and therefore so are the associated public impacts. For a maximally exposed individual worker, the probability of a latent fatal cancer was conservatively equated to that associated with the DOE Administrative Control Level dose of 2,000 mrem/yr (i.e., 0.0008 risk), for both material processing options. The number of expected latent fatal cancers within the worker population did not significantly vary between the two processing options at LANL. This consistency is primarily attributable to similarities in worker exposure rates and modes (i.e., Am-241) during hands-on operations. This range was marked by 0.0056 (Water Leach of Direct Oxide Reduction salts) to 0.0060 (Salt Distillation of Electrorefining/Molten Salt Extraction Salts). It should be noted that these workforce impacts at LANL are equal to or smaller than those associated with all other salt processing options at either Rocky Flats or SRS. Just as at Rocky Flats and SRS, process workers would be expected to receive primarily g -doses from Am-241.

CONCLUSION

Since the Atomic Age began, plutonium has proven itself to be a symbol of ultimate toxicity, due to its ability to essentially "destroy" respiratory systems as its ultra-highly energetic alpha particles make their way around (i.e., through) lung tissues. Because plutonium’s reputation (specifically plutonium-239) is one that is associated with such physiological destruction, much attention has been devoted over the years to preventing said exposures to personnel who work closely with it; this has been primarily accomplished through the use of Personnel Protective Equipment (PPE) and through the service of remote handling equipment (robotics and gloveboxes). In addition, extensive filtration systems have been installed at DOE facilities which house the material in the effort of minimizing potential releases to publicly accessible pathways. With all these mitigation measures in place, are the public or involved workers in danger of significant exposures to this deadly material as a result of the "incident-free" residual material processing actions discussed in this paper? The analytical results appear to render a universal response of "no".

As is clearly evident from the estimated impacts reported in this paper, the potential impacts to members of the public were extremely small for all processing options considered at Rocky Flats, SRS, and LANL. Even though appreciable differences in impact quantities were calculated for various material processing options, at these low levels, a quantitative distinction does not hold any significant relevance in regard to realistically determining potential human health effects to the public. Potential impacts to involved workers are a different situation however. The Department of Energy enforces a "whole-body" worker dose limit of 5,000 millirem/year (10 CFR 835), and an Administrative Control Level of 2,000 millirem/year. Even though ALARA measures will be taken to ensure that these levels are not reached, workers are still expected to receive "appreciable" doses (at least compared to that of the public) from residue process operations. These doses are anticipated to be on the order of roughly 100 to 1,000 millirem per year per worker. It is estimated that over the lifetime of the different material processing operations that the number of latent cancer fatalities would range from about one-fifth of one fatal cancer to seven-eighths of one fatal cancer in a potential workforce of several hundred people. As previously discussed, these health risks are primarily attributable to gamma doses from Am-241 and neutron doses resulting from (a ,n) reactions in plutonium fluoride residues. Interestingly, there are no alpha doses anticipated from the plutonium and americium isotopes since operations are performed inside gloveboxes or other remote systems. These gloveboxes and other systems will protect workers from any potential exposures via the respiratory pathway.

Thus, it is indeed most fascinating (and ironic) to note and reemphasize that these "plutonium workers" are in fact not exposed to any of the "true perils" which plutonium has historically been associated. The latent cancer risks to these workers although significantly larger than that to the public, are still very small.

REFERENCES

FOOTNOTES

a

Draft EIS on Management of Certain Plutonium Residues and Scrub Alloy Stored at the Rocky Flats Environmental Technology Siteb

"Incident-Free" pertains to those operations which do not involve anomalous-type scenarios (e.g., process accidents).