PROJECTIZING INEEL TRANSURANIC WASTE OPERATIONS

T. L. Clements, Jr.; M. R. Martin; M. J. Wolters

Lockheed Martin Idaho Technologies Company

Idaho National Engineering and Environmental Laboratory

ABSTRACT

Decreasing U.S. Department of Energy (DOE) Environmental Management (EM) budgets require improved management approaches to accomplish required waste management activities and meet legally binding agreements established with regulatory agencies or State authorities. A major initiative was undertaken at the Idaho National Engineering and Environmental Laboratory (INEEL) to projectize and integrate programmatic, operational, and technical functions performed to manage stored transuranic (TRU) waste under one organization. This initiative also supported EM efforts to establish a projectized approach for managing activities at the DOE sites as presented in the Project Baseline Summary (PBS). Classical project management elements were addressed as part of defining and integrating the approach to managing INEEL stored TRU waste. Challenges included defining an organization structure that would meet program needs, evaluating project risk, and developing contingency plans that ensure regulatory agreements could be met in an environment of change and uncertainty. Implementing a projectized approach to the stored TRU waste management activities is expected to improve resource identification and allocation, establish critical path schedule, and improve management of project risks.

INTRODUCTION

Since 1970, the Idaho National Engineering and Environmental Laboratory (INEEL) has provided interim storage capacity for transuranic (TRU)-contaminated waste generated by activities supporting United States (U.S.) National Defense needs. Approximately 60% of the nation's current inventory of TRU-contaminated waste is stored at the INEEL-Radioactive Waste Management Complex (RWMC) awaiting future disposal at the Waste Isolation Pilot Plant (WIPP), the designated repository for permanent disposal of this waste form. Facilities have been constructed and processes developed and implemented to support management of this waste. Current capabilities include storage modules meeting Resource Conservation and Recovery Act (RCRA) requirements, nondestructive waste examination and assay systems, intrusive waste examination and sampling capabilities, analytical laboratories for performing volatile organic compound and RCRA-analysis of solidified waste samples, and transportation. Processes for performing characterization and certification functions to demonstrate compliance with WIPP transportation and disposal requirements are in place. Compliance with WIPP transportation and disposal requirements must be demonstrated, through audits and surveillances, to obtain and maintain authority to ship waste to WIPP for disposal. Regulatory authorities also participate in site audits. Waste is currently being certified for future shipment to WIPP in May 1998.

In October 1995, a Settlement Agreement (SA) was reached between Department of Energy (DOE), the State of Idaho, and the U.S. Department of the Navy concerning future receipt of spent nuclear fuel at the INEEL. Conditions set forth in this agreement include conditions that must be met for managing TRU-contaminated waste to allow continued receipt of spent nuclear fuel at the INEEL. Key conditions affecting the near-term management of TRU waste include: (1) completing the first shipment of TRU waste out of the State of Idaho no later than April 30, 1999, and (2) completing the removal of 3,100 m3 of waste (15,000-drum equivalents) by December 31, 2002. Longer-term conditions include completing construction of a privatized waste treatment facility by December 31, 2002; achieving startup of treatment operations by March 31, 2003; and completing removal of all TRU-contaminated waste from the State no later than December 31, 2018.

Finalization and issuance of WIPP regulatory compliance documents and successful startup of WIPP disposal operations are required for the INEEL to achieve the SA commitment for waste removal. Delays in opening WIPP or changes to the current requirements for characterizing, certifying, and transporting waste to WIPP can significantly affect the planning and budgets at each of the DOE TRU waste generating/storage sites. With reduced DOE EM budgets and the need to ensure that SA milestones are achieved, an improved method for managing the INEEL-stored TRU waste was needed.

BACKGROUND

Before the projectization effort, two independent same-level organizations were responsible for performing the technical, programmatic, and operational functions for managing INEEL TRU-contaminated waste. Specifically, one organization managed such activities as determining chemical characterization needs and evaluating, certifying, and reporting analytical results; evaluating and upgrading nondestructive waste assay processes to meet WIPP Quality Assurance (QA) objectives; certifying onsite shipments of waste in the TRUPACT-II shipping container; preparing documents required by WIPP for achieving waste certification authority for waste shipment and disposal; and supporting local and national strategic planning efforts. Technical development activities were also performed that supported the National TRU Waste Program managed by the U.S. Department of Energy-Carlsbad Area Office (CAO) in the areas of waste characterization and transportation.

The second organization was primarily focused on operational aspects, but also was responsible for completing construction projects to expand facility capability and performing needed upgrades to systems and equipment to support waste examination activities. Operational activities included performing waste retrieval and storage operations, performing nondestructive waste examination and assay operations, loading shipping containers, and performing all facility maintenance activities. Support activities included maintaining the environmental, safety, and health authorization basis (safety analysis, RCRA permit, National Environmental Protection Act) and specific institutional programs (radiological protection, industrial hygiene, fire protection, etc.) for operations performed within the RWMC, including both TRU and low-level waste management activities.

This organizational structure, basically a dual management team influencing management of INEEL-stored TRU-contaminated waste, was a periodic source of confusion for overall responsibility and accountability for work completion. This was especially true if the actions or needs of one organization could impact the success of the other organization. Significant resources were expended working integration issues, working coordination and scheduling activities to support overall TRU goals, ensuring availability of operational resources to support programmatic needs, and ensuring no duplication of work activity existed between the organizations.

In January 1997, a decision was made to projectize INEEL-stored TRU waste activities. This decision resulted in a philosophical change to the historical manner in which TRU-contaminated waste type was managed. This decision resulted in consolidating two departments managing the INEEL-stored TRU waste, defining a single organizational structure to manage all work, and implementing an approach to performing work centered around discrete projects that resulted in completing specific products, such as achievement of SA milestones.

APPROACH

In January 1997, a multidisciplinary team was formed to develop a projectized approach for managing INEEL-stored TRU-contaminated waste. This team included senior technical and operational staff, support from the centralized project management organization to ensure compliance with company procedures, and an external management consultant. A 45-day effort was initiated with a focus on developing an integrated work breakdown structure reflecting a product-oriented approach for performing work, defining logic diagrams and schedules necessary to meet project goals, establishing activity-based costs for project activities, and documenting the results in a project plan.

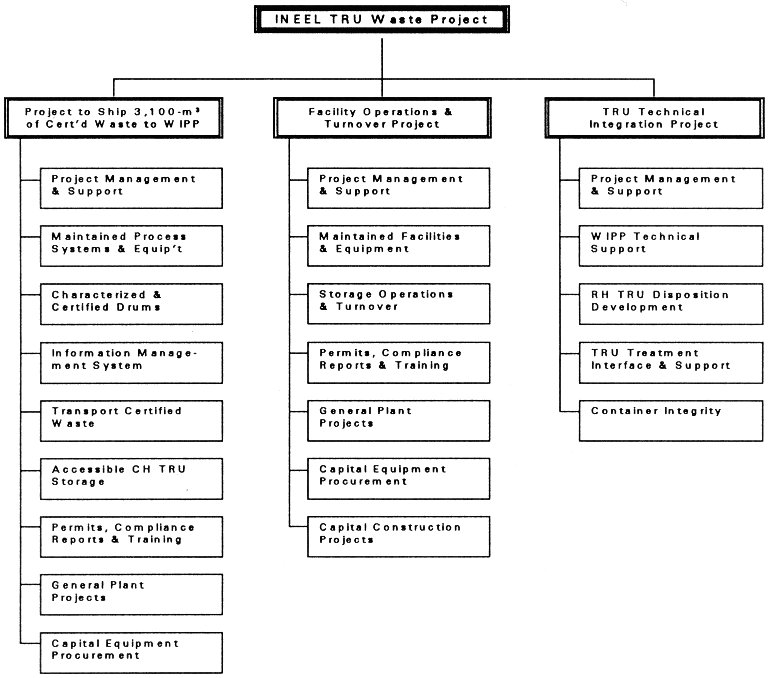

Work Breakdown Structure (WBS)

Development of the INEEL TRU Waste Project WBS required evaluation of all planned activities for both near-term activities, such as meeting SA milestones for untreated waste disposal, and integrating project activities with the longer-term planned privatization of waste treatment activities for TRU waste. Maintaining the facility operations authorization basis for any project activity and accounting for technology development activities performed to support local and national TRU waste management efforts were also addressed.

Challenges to defining a new WBS structure included breaking down paradigms on past work organization, such as by functions or operational activities, rather than work supporting the completion of a project.

As defined by Kerzner (ref 1), a project should consist of tasks and activities that have a specified objective that meets defined specifications, have a beginning and end point, have funding limits and consumer resources (people, equipment, etc.). The WBS was developed around the concept that it should be product-oriented and include the resources necessary to deliver the end product. For the INEEL TRU waste stream, three subprojects were established by the team to define the TRU Waste Project.

The first subproject entails completing near-term milestones established by the SA. Two key products for this project are: Completing the first shipment of TRU-contaminated waste from the State of Idaho by April 30, 1999, and completing the removal of 3,100 m3 of waste (15,000-drum equivalents) from the State by December 31, 2002. The scope of this project includes all work associated with performing chemical, radiological, and physical characterization of waste; performing data collection and validation, and reporting waste parameters to WIPP; preparing waste for shipment to WIPP; managing the accessible waste storage buildings; maintaining project-specific equipment (primarily the nondestructive examination and assay systems); and conducting necessary environmental, health and safety functions to maintain permits, perform project-specific training, and verify project compliance with facility authorization requirements.

The second subproject provides facility operations and turnover, and government furnished equipment (GFE) to the subcontractor that will perform privatized treatment of the remaining stored TRU-contaminated waste inventory after year 2002. The scope of this project includes managing facilities and waste not directly supporting the removal of 3,100 m3 of waste by year 2003, including the TRU Storage Area-Retrieval Enclosure and the berm-stored covered waste; managing remote-handled TRU waste stored at the Intermediate Level TRU Storage Facility; maintaining RWMC buildings, non-3,100-m3 project specific equipment and systems, and rolling stock; performing specific projects such as addressing management of U-233 waste; and ensuring the authorization basis for the entire RWMC facility are in compliance with permits, regulations, and DOE Orders. This project activity extends through the end of year 2006, at which time functions not being performed by the privatized subcontractor for TRU waste treatment will be transferred to a Long-Term Treatment, Disposal, and Storage Project as delineated in the PBS.

The final subproject provides integration of TRU waste activities through year 2006. The scope of this project includes work performed for the DOE-CAO National TRU Program including studies to improve transportation of waste, conducting performance demonstrations to assess DOE site compliance with radioassay and solidified waste analysis QA objectives, and supporting use of mobile headspace gas equipment; supporting Mixed Waste Focus Area efforts to demonstrate commercial radioassay capabilities; developing technical capabilities needed to characterize, certify, and transport remote-handled TRU-contaminated waste to WIPP for disposal by year 2006; and supporting new business initiatives.

Figure 1. INEEL TRU Waste Project WBS Summary Level Overview.

The development of the WBS was one of the most important activities for restructuring and establishing a framework within which the INEEL stored TRU waste activities would be performed. Additionally, the WBS served as an effective communication tool to describe the manner in which the work performed by two separate organizations would be integrated into a single approach.

Schedules and Cost

Once the WBS was approved by management, Work Element Managers were selected to develop the logic diagrams and schedules that would support project completion. The Work Element Managers were selected from both organizations based on technical or operational capability and knowledge of the specific work element products and services. A challenging aspect of developing the logic diagrams and schedules was due to the repetitive nature of the operations planned and the limited amount of data concerning the waste from which estimates had to be made to support scheduling activities. Not all drums entering the characterization process follow the same path. Some drums may be rejected early due to noncompliance with WIPP transportation and disposal criteria, others may require intrusive examination and sampling to verify compliance with WIPP characterization requirements. Because the INEEL-stored waste was generated before the current WIPP transportation and disposal criteria were established, uncertainties exist concerning the degree to which the available waste inventory can be expected to meet requirements. Extensive evaluation of the projected waste inventories to be processed and of modeled characterization facility throughput rates was performed to support development of the schedules.

Existing INEEL project controls scheduling software did not meet the needs for developing integrated detailed project schedules. Primavera® was the scheduling software selected to support projectization efforts. This selection was primarily based on the availability of in-house personnel familiar with this scheduling package because of the short timeframe available to the project team to complete a draft project plan for the shipment of 3,100 m3 of waste to WIPP.

In general, detailed cost estimates existed for most of the planned activities before the projectization effort. However, evaluation and revision were necessary to address the revised project strategic approach, eliminate areas of duplicated work scope, ensure specific work discipline codes were used to support manpower projections and staffing needs, and develop more comprehensive cost estimates for level-of-effort planning areas. If definitive workscope and end products could not be defined, the dollars were eliminated. An independent team of cost estimators was used to review and validate the quality and completeness of cost estimates generated by the work element managers.

Primavera® schedules incorporating resource needs were developed, and now provide the detailed basis from which project status is determined on a monthly basis for reporting to internal and DOE-ID management. Additionally, these schedules are used to assess the impact of delayed activities. For example, if characterization system throughput rates are not consistent with project assumptions for throughput, evaluations can be made of alternative work schedules to increase operating time and correct negative schedule variances. This is especially important when dealing with legally binding milestones.

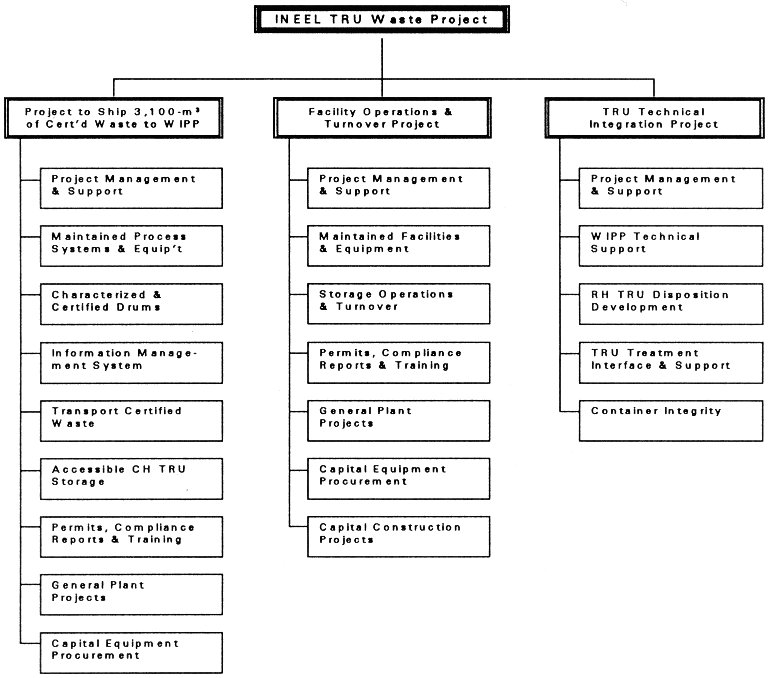

Organizational Structure

Implementing a projectized approach to performing INEEL-stored TRU waste activities also required transition from a functional or operationally-based organization, to a project-organization structure to meet this new work approach. Key objectives of defining a new organizational structure included single-point accountability for producing products and services required from each project; placing responsibility and authority for scope, schedule, and costs within the project; and using the existing trained, qualified resources to complete the work efficiently and in compliance with DOE Orders, Federal and State Regulations, company requirements, and WIPP transportation and disposal criteria.

A variety of organizational structures were evaluated. These structures ranged from pure product to pure matrix structures, as defined by Kerzner (ref. 1). The organization structure selected is a modified matrix approach. It places total responsibility and accountability for completing the project in accordance with the technical, cost and schedule baselines with a Project Manager. Each project, however, draws on resources from four work groups within the organization: Maintenance; Operations; ES&H; and Business Support. These work groups provide the necessary trained and qualified resources necessary to complete project work. This approach minimizes the total number of people reporting to the Project Manager, compared to a pure product approach, and increases flexibility in shifting resources between projects based on work demands and schedule needs. Control Account or Work Element Managers report to the Project Managers and are accountable for completing products defined within an assigned WBS element. These individuals are also responsible for communicating with and obtaining necessary support from the work groups, monitoring performance to cost and schedules, and ensuring completed products are technically sound and of high quality.

Figure 2. Overview of organization structure implemented October 1, 1997.

RISK MANAGEMENT AND CONTINGENCY PLANNING

Risk management and contingency planning were performed for the subproject dealing with removal of 3,100 m3 of TRU waste by December 31, 2002. The purpose of this planning is to anticipate potential problems that could preclude successful project completion, develop appropriate corrective actions, and make provisions for implementing corrective actions.

Planning for removal of 3,100 m3 of waste by December 31, 2002 uses assumptions which, in themselves, equate to risks. Evaluating these assumptions and the multifaceted risks they represent along with a careful review of the planned waste examination operating and handling sequences define the risk bases for planning the technical contingency actions. Nearly all project risks are related to three basic issues:

Numerous critical activities, assumptions, and conditions can influence the successful completion of a project. To identify and understand the uncertainties and risks, a Contingency Planning team was organized of individuals representing key TRU waste functions including facility operations, maintenance, engineering, inventory management, permitting, Radiological Controls, programs, and Environment, Safety and Health (ES&H). Most references consulted for suggestions on the contingency planning process addressed construction projects and financial contingencies, rather than complex operations issues, facility operations, and regulatorily controlled schedules. The techniques ultimately used by the team were adapted from two source documents:

The team began by identifying potential deviations from the expected conditions in terms of the probability of occurrence and the potential impact on the Project. This was followed by a cause-and-effect analysis of the parameters. "Expected conditions" are those things which can be anticipated to occur during the life of a project; a "deviation," on the other hand, is a departure from expected conditions (i.e., the baseline) which has a realistic probability of occurrence. Whenever possible, each potential deviation was evaluated in terms of both the probability of occurrence and the probable impact on the Project. Rankings were developed using the numerical product of the occurrence-probability (an ascending linear scale from 1 to 9), and the impact (a log scale from 100 - 103). The impact ranking was a rough reflection of the recovery time in days. The difference in the scales mirrored the sensitivity of the Project to the milestone dates.

Optional contingency actions and mitigating strategies were subsequently identified. These were evaluated in terms of implementability and effectiveness. Rough-order-of-magnitude cost estimates were developed to support selection of contingency actions. Finally, monitoring plans were also identified.

All the identified events and technical issues that would cause deviations from the Project technical baseline were arranged into one of three categories:

The actions developed through contingency planning, while not complex, involve more detail than is appropriate for this paper. The contingency actions are summarized below:

Monitoring Plans: Trending analyses have been implemented to detect problems or anticipate their onset before they can become significant in terms of impact on project objectives. Roughly, a dozen key areas were identified. Examples range from monitoring developments accompanying the issuance of WIPP Part B Permit, to monitoring the operation-specific rejection rates and processing times.

Actions Requiring Customer Support: This area covers offsite DOE interfaces and identified areas appropriate for clarification and/or agreement. The intent is to ensure that a miscommunication or misunderstanding does not lead to significant, inadvertent impacts such as schedule delays.

Recommended Actions Pertaining to Waste Inventory: Most identified potential issues can result in an inventory shortfall and because of the serious impacts of such events, the highest priority must go to contingency actions which deal effectively with these concerns. Two contingency-action recommendations were identified which offset the impacts of "inventory shortfall." Briefly, the first action would restore drums stored in overpacks (not otherwise examinable) to the potentially certifiable inventory. This action, alone, could overcome a shortfall of up to 1,000 drums. The second action would provide the transport of boxed waste, which cannot be examined or repackaged at the INEEL, to another DOE site for repackaging. The first recommendation will be implemented within the next year, the second will be planned and developed for implementation at a later date, should it be required. Combined, these actions represent an opportunity for a graded response contingent on the type and the magnitude of the impact(s), but not requiring significant pre-staging efforts or costs.

Recommended Actions Pertaining to Other Technical Issues: Issue-specific conditions resulted in recommendations for implementation or development of nine separate actions. Some actions were already in the Project Plan (e.g., implementing independent, on-line reject confirmation), while others were essentially no-cost actions (e.g., performing nondestructive examination/nondestructive assay (NDE/NDA) on suspect drums before overpacking).

Strategic Alternatives for Future Consideration: Several strategic issues were identified in the course of executing the analyses. These were identified with strategic alternatives because they represent a significant planning departure from the current Project baseline. An example is the recommendation to evaluate two-shift operations in the facilities used for nonintrusive examination. This alternative may become necessary to develop the required number of certifiable drums in the time available, if the Project assumption for processing rates proves too optimistic.

PROJECT PLAN DEVELOPMENT

A project plan for the Shipment of 3,100 m3 of TRU Waste to WIPP was completed. The project plan is a tool to communicate objectives, approach, deliverables, uncertainties, and methods for monitoring and controlling work. Key elements of the plan include identification of the technical baseline and project assumptions; management controls including project change control; the requirements for quality, safety, security; and presentation of schedules, cost, and resource needs. The plan received extensive internal management and technical review. Enhancements since the initial draft include the incorporation of a detailed risk management and contingency planning and independent review by the Army Corps of Engineers during Summer 1997. Project plans have been drafted for the two remaining TRU waste subprojects.

SUMMARY

A projectized approach to managing INEEL stored TRU waste activities was developed and implemented. It is expected to improve overall management control and accountability for scope, schedule, and cost baselines for completing project activities.

Project uncertainties and declining budgets demand close monitoring of progress against an established baseline to identify deviations. Early detection of deviations allow corrective actions or contingency plans to be implemented as early as possible. This is particularly important when legally binding agreements have been established with regulatory agencies.

REFERENCES