OVERVIEW OF DEVELOPMENT IN CONTINUOUS EMISSIONS MONITORING FOR MIXED WASTE TREATMENT

William J. Haas, Jr.

Ames Laboratory

Iowa State University, Ames, IA 50011

Stephen J. Priebe

Lockheed Martin Idaho Technologies Company

Idaho National Engineering and Environmental Laboratory

2525 S. Fremont, Idaho Falls, ID 83415-3875

Daniel B. Burns

Westinghouse Savannah River Company

Savannah River Technology Center, Building 773-42A, Aiken, SC 29808

Nina Bergan French

Sky+, Inc.

7000 Thornhill Drive, Oakland, CA 94611

Paul M. Lemieux

U. S. Environmental Protection Agency

National Risk Management Research Laboratory

Research Triangle Park, NC 27711

David A. Hutchins

U.S. Department of Energy

Oak Ridge Field Office

P. O. Box 2001, Oak Ridge, TN 37831

ABSTRACT

Waste treatment is an important application and market area for continuous emissions monitors (CEMs). In the mixed waste treatment area, for example, U.S. Department of Energy (DOE) has legal responsibility for treatment and disposal of a current inventory of more than one million cubic meters of low-level, high-level, and transuranic mixed waste. Future DOE decontamination, decommissioning, and environmental cleanup activities will likely bring the total to more than two million cubic meters. Thermal treatment processes such as vitrification, incineration, and plasma treatment will be employed for most of this waste, and all will be treated and disposed in compliance with applicable laws and regulations. CEMs will likely be required because of public concern and insistence that potentially hazardous emissions from the treatment processes be strictly limited, continuously monitored, and documented.

This paper provides an overview of the developing and envisioned regulatory and stakeholder situation with respect to CEMs and DOE waste treatment, and an overview of the status of currently available and emerging CEMs for particulate matter, Hg, multi-metals, dioxins / furans, and radionuclides. It provides technical descriptions of the technologies and performance information based on recent tests conducted under the auspices of the Mixed Waste Focus Area (MWFA), the Characterization, Monitoring and Sensor Technology Crosscutting Program (CMST-CP), and the U.S. EPA. It also identifies the CEM technology developers and describes the status and prospects of CEM development activities.

The primary goal is to acquaint potential CEM users with the availability and performance of CEMs for support of DOE waste treatment operations. A secondary goal is to stimulate thinking among both CEM developers and potential users on how to implement continuous monitoring, perhaps in combination with non-intrusive feed stream characterization and improved air pollution control, to help ensure safe and affordable treatment, proper performance, and public acceptance of thermal treatment facilities.

INTRODUCTION

Continuous emissions monitors (CEMs) can provide several benefits for mixed waste treatment. They can enable better control for safe, environmentally compliant operation of treatment facilities, provide documentation of such operation, and help provide greater assurance of the quality of the final waste forms. These benefits address important public concerns regarding the siting and operation of incinerators or other thermal treatment equipment. Hence, quality CEMs can improve public acceptance of such facilities.

Hazardous air pollutants (HAPs) are the emissions of concern for the CEMs addressed here. Congress has identified 189 HAPs [42 U.S. Code 7412]. They are regulated under the Clean Air Act and Amendments of 1990. The HAPs can be considered in three main classes: (1) hazardous organic compounds, (2) hazardous inorganics, and (3) radionuclides. Particulate matter (PM) is also of concern because it can be monitored fairly easily and because PM can serve as an indicator of the presence of HAPs.

For waste treatment processes such as incineration and vitrification, the organic emissions of greatest concern include chlorinated organic compounds such as the extremely toxic tetrachlorinated dibenzo-p-dioxins (TCDDs), dibenzofurans (TCDFs), and polychlorinated biphenyls (PCBs). The hazardous inorganic emissions of concern include gaseous inorganic pollutants such as CO, NO, NO2, and SO2, for which CEMs are required by regulation and are already widely used, and Cl2, and HCl, which are addressed by the proposed MACT rule [EPA, 1996]. Other hazardous inorganic emissions that are already regulated include the so-called "heavy metals." These include the elements and compounds of two categories of metals: (1) the so-called MACT-rule metals and (2) other heavy metals classified as toxic by RCRA. The MACT-rule metals are Hg, the semi-volatile metals Cd and Pb, and the low volatility metals As, Be, and Cr. The other heavy metals, regulated under RCRA, are Ag, Sb, Ba, Co, Mn, Ni, Se, Tl, and V. The MACT-rule metals have that name because, according to the current EPA notice of proposed rulemaking [EPA, 1996], emissions of these metals from hazardous waste combustors will be regulated under the joint authority of the Clean Air Act and RCRA. Radionuclides, the final category of HAPs, are also a matter of concern for mixed waste treatment. Emissions of these materials are regulated under the Clean Air Act and DOE orders, and CEMs for radionuclides are desired for demonstration that treatment facilities are continuously operating in a safe and regulatory compliant manner.

Within the U. S. Department of Energy Office of Environmental Management (DOE EM), the Mixed Waste Focus Area (MWFA) and the Characterization, Monitoring and Sensor Technology Crosscutting Program (CMST-CP) are working together to provide CEMs to support safe, effective, and regulatory compliant mixed waste treatment and disposal. The MWFA is responsible for providing the right treatment technologies and the CMST-CP is charged with providing the necessary characterization and monitoring tools for such treatment. The two programs are working together on CEMs because, according to our best information, regulators will be treating DOE mixed waste thermal treatment facilities as hazardous waste incinerators. Furthermore, EPA has clearly stated its preference for CEMs as the preferred approach for ensuring regulatory compliance [EPA, 1996, page 17417]:

"The top tier of the compliance monitoring hierarchy is the use of a continuous emissions monitor system (CEMS) for that HAP or standard. In the absence of a CEMS for that HAP or standard, the second tier is the use of a CEM for a surrogate of that HAP or standard and, when necessary, setting some operating limits to account for the limitations of using surrogates. Lacking a CEMS for either, EPA sets appropriate feedstream and operating parameter limits to ensure compliance and requires periodic testing of the source."

Particulate matter (PM) CEMs will be required when the MACT rule is promulgated; Hg CEMs will likely be required as soon as systems that meet EPA performance specifications are shown to be available. Also, although the MACT rule will not mandate multi-metals CEMS, it will most likely offer incentives for voluntary implementation. According to the proposed rule, the application of CEMs for hydrogen chloride (HCl), chlorine (Cl2), mercury (Hg), semi-volatile metals (SVMs), and low-volatility metals (LVMs) can replace feedstream analysis for those components for regulatory compliance and remove them from consideration during required comprehensive and confirmatory tests. This is important for mixed waste because of the DOE ALARA requirement, i.e., to keep worker radiation exposure "as low as reasonably achievable" and because both the feedstream analyses and the testing, the latter comparable to the Resource Conservation and Recovery Act (RCRA) trial burn, are high cost activities. In addition, waste feed characterization, a RCRA requirement, can potentially be reduced significantly when CEMs are used. Also, the use of CEMs would eliminate the reliance on process operating parameters for regulatory compliance. For example, a facility would no longer use process operating parameters such as baghouse differential pressure, scrubber flow, or total offgas flow to show compliance with the particulate matter emission standard. Instead, a particulate matter CEM would verify continuous compliance with the standard, and waste feed cutoffs would no longer be tied to several process operating parameters.

Needs

The MWFA has performed thorough investigations of technologies available for mixed waste treatment, identified 30 technology deficiency areas, and prioritized those deficiencies with respect to their importance for achieving safe, effective, regulatory compliant, and affordable waste treatment [DOE, 1995, 1997]. The MWFA identified five deficiencies in the monitoring area: (1) Hg monitoring, (2) heavy metals monitoring, (3) alpha-emitting radionuclides monitoring, (4) volatile organic compounds monitoring, and (5) radionuclide distribution or monitoring. According to the MWFA, these deficiencies have nearly indistinguishable priorities in the range of 11 to 18 (1 is top priority).

Information concerning DOE EM technology needs was also gathered independently by the Site Technology Coordination Groups. According to these, valid methods for continuously monitoring mercury, heavy metals (Cd, Pb, As, Cr, and Be), and dioxins are needed to help ensure that emissions from MW thermal treatment facilities are maintained below permitted limits.

Teamwork

The CMST-CP and the MWFA began to work together on CEM activities in 1995; that teamwork continues today. In 1996 they formed an ad hoc CEM working group, which identified available monitoring technologies, assessed the technologies known to be under development, and identified technology gaps. In September 1996, they completed a draft CEM Technology Development Strategy document [French et al, 1996]. The strategy document, which is intended to be a dynamic entity, summarized the needs and opportunities and outlined a vision and proposed plans for how the CEM needs would be addressed.

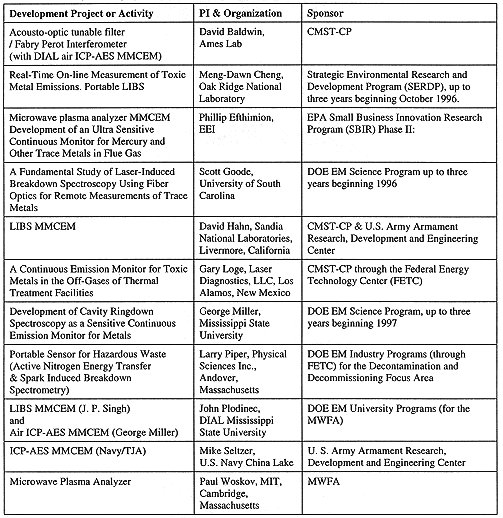

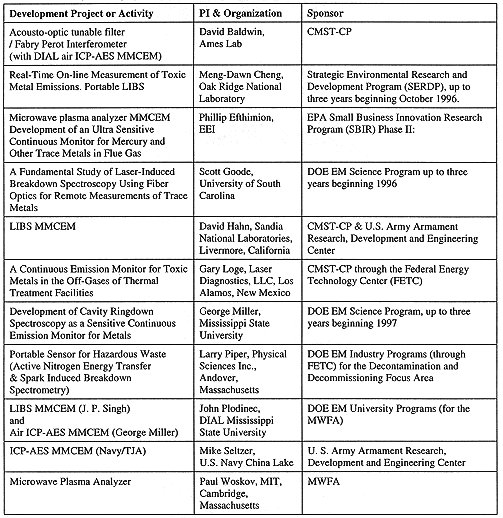

One of the key products of the working group effort was a list of science and technology development projects that are applicable to process and emissions monitoring for mixed waste thermal treatment and were already funded by the federal government. The portion of the list that addresses the multi-metals CEM (MM CEM) portion of that work is given in Table I. Other projects address other process monitoring and CEM categories.

Table I. Federally Funded Projects Related to Multi-Metals CEMs

The number of projects related to MM CEMs is impressive, and the total annual funding investment is in the millions of dollars. The number of federal programs providing funding for these projects, often with little communication with the other funding programs or offices, is equally impressive. Therefore, one obvious part of the strategy to accelerate the availability of the needed CEMs was to take advantage of the work funded by all these programs and to try to develop a single, coordinated technology development framework for the projects. Hence, the MWFA and the CMST-CP led in the formation of the Interagency CEM Technology Development Coordination Committee and Working Group. These bodies convened for the first time in January 1997. The ICCC (shorthand for the Interagency CEM Coordination Committee) includes persons with funding authority and program direction authority for the projects of interest. The following organizations are represented: DOE-EM (MWFA and CMST-CP), DOE Office of Fossil Energy, EPA (Office of Solid Waste, the Office of Air Quality Planning and Standards, and Office of Research and Development), and Department of Defense (U.S. Army Demilitarization Technology Office, the U.S. Air Force, and the Strategic Environmental Research and Development Program (SERDP)). The ICCC meets only once or twice a year, but is supported by the Interagency CEM Technology Development Working Group. The latter provides information and recommendations to the ICCC. The principal purpose of both groups is to coordinate their activities in a way that accelerates CEM development, validation, and application. The principal collaborative activities undertaken so far are: (1) promotion of information sharing at the sponsor and principal investigator levels, and (2) collaboration in conducting quantitative evaluations of the performance of CEMs in realistic test environments.

CEM PERFORMANCE TESTING

CEM performance tests are important to regulators, instrument developers, and potential CEM users. EPA has published draft performance specifications (requirements) for CEMs [EPA, 1996b, 1996c, 1996d]. Instruments that satisfy the PS can be used to fulfill CEM requirements or to take advantage of incentives addressed in regulations; instruments that don't satisfy the EPA PS don't have regulatory value. Developers and users need test results to see how the various competing CEMs perform under realistic operating or test conditions. The test results help guide development and application decisions.

DOE (MWFA and CMST-CP) and EPA have collaborated in conducting several CEMs performance tests pertinent to MW thermal treatment. The tests are listed below; summary descriptions of the tests and their results are provided in succeeding portions of this paper.

The following approach was used for all the tests: The flue gas was spiked to provide pollutant concentrations near the EPA emission limits. The CEMs were used to analyze the flue gas while the concentrations were also simultaneously measured using conventional, laboratory-based EPA Reference Methods. The performance of the CEMs was measured both in comparison to the results obtained by the EPA reference methods and in comparison to draft performance specifications (PS) proposed by the EPA [EPA, 1996b, 1996c, 1996d].

The key elements of the draft PS for multi-metals CEMs are given below, for example.

DOE / EPA CEMs Performance Test at the EPA Incineration Research Facility, August, September 1995.

In two separate test periods in August and September 1995, DOE and EPA jointly conducted one-week tests of 11 CEMs at the EPA Incineration Research Facility (IRF) in Jefferson Arkansas. The IRF was a pilot scale rotary kiln incinerator with a wet air pollution control system. The CEMs included four Hg CEMs, two multi-metals CEMs, four volatile organic compounds CEMs, and one semi-volatile organics CEM. A detailed description of the IRF tests and results has been published [Ghorishi et al, 1996]. Some key overall results can be summarized as follows:

Extended Duration Particulate Matter (PM) CEMs Testing, September 1996 through May 1997.

During this period, EPA and DOE conducted extended duration testing of PM CEMs at the DuPont Experimental Station hazardous waste incinerator located in Wilmington, Delaware. The purpose was to determine what commercially available PM CEMs could meet the EPA draft performance specification (PS11) and calibration statistical data quality objectives [EPA, 1996c] under actual field use conditions. Five PM CEMs were tested:

The air pollution control system at the DuPont facility included a spray dryer, venturi scrubber, spray absorber, and an electrodynamic venturi. The flue gas conditions were

![]()

The test procedure and findings have been described in a draft report [EPA, 1997]. The key findings from the extended duration PM CEMs testing at DuPont were:

Extended Duration Hg CEMs Testing, December 1996 through May 1997

During this period, DOE and EPA conducted extended duration testing of Hg CEMs at the Holnam Inc. cement kiln located in Holly Hill, South Carolina. The purpose was to determine what commercially available Hg CEMs could meet the EPA draft performance specification (PS12) and calibration statistical data quality objectives [EPA, 1996d] under actual field use conditions. Three monitors were tested:

The Holnam Inc. facility was equipped with an electrostatic precipitator; the flue gas conditions were as follows:

![]()

The key findings from the extended duration Hg CEMs testing were:

DOE/EPA Multi-Metal CEMs Test at the EPA Rotary Kiln Incinerator Simulator, April 1996

In April 1996 DOE and EPA conducted a one week test of multi-metals CEMs at the EPA rotary kiln incinerator simulator, Research Triangle Park, North Carolina. The principal goal of the test was to determine the Relative Accuracy of the CEM results as compared to EPA Method 0060 (Method 29). Three CEMs were tested:

Information concerning this test and its results has been also been published [Haas et al, 1997]. At the concentrations tested, the Navy/TJA ICP-AES system measured all seven test metals; the LIBS systems measured only one to four metals. The Navy/TJA system achieved 50 to 100% Relative Accuracy levels¾ better than the other CEMs but not good enough to meet the draft EPA PS [EPA, 1996b]. The detection limits need improvement for all these CEMs. The Navy/TJA system needs improvement for Hg; the LIBS instruments need detection limit improvement for all seven metals. As configured for this test, i.e., with only one spectrometer each, neither of the LIBS instruments could simultaneously observe the desired spectral lines for all seven of the target metals. As a result, for any given metal, the LIBS systems typically recorded data for only about 30% of each RM measurement period. The Navy/TJA system, on the other hand, was able to observe all seven of the target metals simultaneously.

Response times for all the instruments, to the extent they could be estimated, appeared to satisfy the draft PS.

Bench-Scale Jet-REMPI / TOFMS Dioxin CEM Feasibility Test

In September and October 1996 DOE and EPA collaborated in conducting bench scale feasibility testing of an innovative system for real-time detection of dioxins [French et al, 1997]. The Jet-REMPI / TOFMS system, provided by DLR Stuttgart, uses a pulsed tunable laser to selectively ionize jet-cooled molecules found in the flue gas by resonance enhanced multi-photon ionization (REMPI) and then detects the ionization products by time-of-flight mass spectrometry (TOFMS). The tests were conducted at the EPA National Risk Management Research Laboratory, Research Triangle Park, North Carolina, The tests employed a gas chromatography system to generate known concentrations of pure mono- through tetra-chlorinated dioxins for examination by the Jet-REMPI / TOFMS system.

The tests provided the first real-time measurement of dioxins in simulated flue gas (air)¾ with a detection limit of 30 ng/m3 for 2, 7 dichlorodibenzo-p-dioxin. Detection limits for the tetrachlorinated dibenzo-p-dioxins were estimated to be approximately 1000 ng/m3, three to six orders of magnitude greater than what would be required for a dioxin CEM capable of measuring dioxins at levels near the proposed emission limit. Hence, one conclusion of the test was that sample preconcentration and particle¾ gas separation, both without impact on the dioxin/furan chemistry, will be necessary and crucial parts of any successful dioxin/furan CEM approach. The positive test results also reinforced EPA interest in a dioxin CEM. Today, Jet-REMPI/TOFMS is viewed as one potentially successful CEM approach. Other approaches under consideration include fast gas chromatography with mass spectrometer detection and gas chromatography with surface acoustic wave sensor detection. The ultimate goal is good dioxin control and documentation of the same. Therefore, because dioxin detection requirements are so challenging, it will be important in future dioxin CEM development to closely coordinate that development with identification of dioxin formation mechanisms, precursors, measurement surrogates, and control strategies¾ all with the goal of identifying things that are easier to measure than dioxins but accurately indicate toxicity attributable to dioxins.

Multi-Metals CEMs Test at the DOE Oak Ridge TSCA Incinerator (TSCAI), September 1997

The purpose of this test was to investigate the deployment potential of three multi-metals monitoring systems under TSCAI stack conditions and, based on the findings, to make recommendations concerning future testing, evaluation, and/or deployment of a metals monitor. Three multi-metals monitoring systems were tested:

The TSCAI was operated with radioactive organic liquid and aqueous waste feeds. The air pollution control system included a water quench, venturi scrubber, packed bed scrubber, and two stages of ionizing wet scrubber. The flue gas conditions were:

![]()

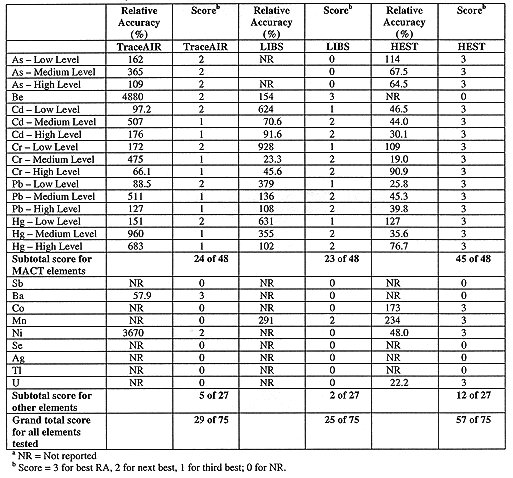

The test considered the performance of the monitoring systems for the MACT rule elements, As, Be, Cd, Cr, Pb, and Hg, and for other elements known to be present in the test waste, Sb, Ba, Co, Mn, Ni, Se, Ag, Tl, and U. Most of these latter elements will potentially be regulated under RCRA in the new TSCAI permit. The feed was spiked with As, Cd, Cr, Pb, and Hg at three test levels (low, medium, and high). The target concentrations of these MACT rule elements in the flue gas were 10, 100, and 500 m g/dscm. Measurements made by the monitoring systems were compared with those obtained from samples collected concurrently using EPA Reference Method 29 (multi-metals sampling train). Six Method 29 runs were collected at each of the three target concentration levels. The Method 29 samples were analyzed on site using EPA SW-846 methods 6010b and 6020. The HEST filter samples were also analyzed on site, using wavelength dispersive X-ray fluorescence spectrometry.

The TSCAI test team prepared special criteria for evaluation of the deployment potential of the test monitoring techniques at the TSCAI. The principal criteria focused on two questions:

The purpose of the second, less demanding, set of criteria was to discount the effects of the RM imprecision, if any. Additional criteria considered uptime, response time, calibration and check procedures, and automation.

The Relative Accuracy results are presented and summarized using a scoring method in Table II.

Table II. Relative Accuracy Results from the TSCA Incinerator Testa

Some of the highlights of the TSCAI test findings are as follows:

Many additional findings and conclusions, particularly with respect to the evaluation of deployment potential at TSCAI and the additional criteria mentioned above, are contained in the draft test report [Dunn et al, 1998]. We are grateful to Dr. Dunn and coworkers for providing early access to the test results.

DOE/EPA Multi-Metals CEMs Test at EPA Rotary Kiln Incinerator Simulator, September 1997

In this second one-week test at the EPA RKIS, the performance of nine MM monitoring techniques was evaluated:

In addition, Laser Diagnostics, Los Alamos, New Mexico, performed special post-processing of some LIBS data obtained from the Sandia instrument. Also, DIAL and Ames Laboratory investigators collaborated to apply a high resolution interferometric spectrometer (HiRIS) for measurement of emission signals from the DIAL air ICP.

The principal findings from the September 1997 MM monitoring tests were:

These and other findings, conclusions, and recommendations are described in French et al, 1998.

Radionuclides CEMs

The need for a radionuclides CEM is unique to DOE. Radionuclide emissions are regulated under DOE orders and the Clean Air Act National Emission Standards for Hazardous Air Pollutants (NESHAPS). The regulation is risk based, limiting the exposure of a maximally exposed individual at the site boundary or beyond to no more than 10 mrem/year. As a result, a model is required to translate from that maximum exposure level to equivalent stack gas concentrations. An assessment of the levels of radionuclides that might be emitted from mixed waste thermal treatment facilities using multiple High Efficiency Particulate Air (HEPA) filters has been performed [French et al, 1996]. These calculations indicate that such facilities will emit extremely low levels of radionuclides. Based on those calculations and the sensitivity required to conduct continuous monitoring at levels near the emission limit, it appears currently available and emerging radionuclide monitors have insufficient detection capability for CEM use if measurement cycle times must be as short as the two minute response time EPA has proposed in the draft performance specification for multi-metals CEMs.

Current activities in the radionuclides CEM area include (1) testing a commercially available monitor (EG&G Berthold) at Oak Ridge National Laboratory, and (2) efforts to deploy a near-real-time alpha CEM (developed at Los Alamos National Laboratory) at the Oak Ridge TSCA incinerator. The Berthold monitor operates by sampling and analysis. Depending upon the sample time, one can achieve very good sensitivity (detection limits) at the expense of real-time monitoring capability. A typical sampling time is about one hour. The Los Alamos instrument, known as a flow through alpha monitor (FTAM), is capable of an analysis in as little as 15 seconds, but with less sensitivity than the Berthold. Both these monitors depend on counting disintegrations, so sensitivity depends on the length of time over which the measurement is made. When the sampling and counting times for the Berthold and FTAM instruments are comparable they have comparable sensitivity. Potential advantages of the FTAM over the Berthold instrument are tolerance to saturated water vapor and somewhat higher temperature, and the ability to measure the entire stack gas flow rather than only an extracted sample. The principal advantage of the Berthold monitor is its commercial availability.

Status of PM, Hg, Multi-Metals, and Radionuclides CEMs

Of the CEMs addressed in this paper, only PM CEMs have been shown to meet the proposed EPA performance specifications. Based on the results of the recently completed extended duration testing, Hg CEMs are close but have not been demonstrated to meet EPA performance specifications. The Hg CEMs do appear to have sufficient detecting power to make useful measurements at levels near the emission limit. However, their gas sampling and conditioning arrangements have problems with particulates, acid gases, and moisture, and are consequently unreliable. HCl/Cl2 CEMs are commercially available, however EPA has not yet validated their performance. No multi-metals CEMs that meet the performance specification proposed by EPA are available. The ICP-AES system advanced by the U.S. Navy / Thermo Jarrell Ash team has shown the ability to monitor all the MACT metals. In addition, it has come close, but has not yet achieved Relative Accuracy performance that satisfies the proposed EPA PS. (There is, in fact, some question whether an additional set of independent EPA reference method measurements would meet the requirement for Relative Accuracy £ 20%.) In the case of radionuclides, the available and emerging systems do appear to have sufficient detection power to monitor flue gas radionuclide emissions at levels corresponding to NESHAPS limits, but only for measurement and reporting periods of one hour or longer. Shorter measurement and reporting intervals are supported by these instruments, but then sensitivities decrease to the point where only emission levels much larger than the emission limit can be detected. In that mode the radionuclide CEM could function as an alarm¾ notifying the facility operator and the public that something had gone wrong and that emission limits for radionuclides had been exceeded.

CEM NEEDS AND PATH FORWARD

CEM Needs

Improved sampling and sample conditioning systems are needed for Hg CEMs. When such systems are provided, the present, commercially available Hg CEMs will likely be able to meet the proposed EPA PS. In the case of the MM CEMs, improved Relative Accuracy is needed. Generally, because Relative Accuracy is poorest at concentration levels approaching the limits of detection, this means improved power of detection is required. At this time, the deficiencies in RA and powers of detection seem to be more important for the CEMs that employ lasers and fiber optics (LIBS, SIBS) than for those that do not (ICP-AES).

The lack of field calibration systems and procedures is an important deficiency for Hg CEMs and most of the MM CEMs. Such systems and procedures are essential for performing the calibration checks required in the PS. More important, however, valid calibrations are essential for accuracy in the concentration measurements. Because the calibrations embody the relationships between the actual analyte concentrations and all the instrumental and sample matrix parameters that impact the measured concentrations, and because those parameters cannot be warranted as constant, we must have accurate calibrations to begin with and they must be updated from time to time under actual operating conditions. For CO and O2 CEMs, the availability and use of "calibration gas" from a pressurized cylinder satisfies field calibration requirements. Permeation tubes that release Hg at a constant, known rate under certain fixed temperature and pressure conditions have been developed for use in the laboratory. However, these systems are not well suited for use in the field. Reliable delivery of known concentrations of Hg in the field at levels near the emission limit is very difficult, in part because, at those levels, Hg appears to be absorbed by materials that are ordinarily considered inert [Roberts et al, 1996].

A lower cost way of validating MM CEM performance is also desired. The current way¾ comparison to the results of EPA reference methods that employ flue gas sampling and analysis in an off-site analytical laboratory¾ is too expensive.

Extended duration tests of PM and Hg CEMs have been conducted; the operations of these systems appear to be sufficiently automated. The same is not yet true for the MM CEMs. At present, the operation of these systems appears to require almost constant attention from a human operator. To succeed in commercial or regulatory compliance monitoring these systems will require automation to reduce their dependence on personnel for routine operational activities including quality assurance activities and data management and reporting operations. A variety of CEM costs will be important. The capital, operating, and maintenance costs will all have to be balanced against the benefits of CEM application.

Path Forward

We think the priority actions listed below make sense in light of DOE EM and EPA objectives and what we have learned from the performance tests.

We intend to work further on these ideas and plans with the Interagency CEM Technology Development Working Group. We also intend to get input and generate support from the Interagency CEM Technology Development Coordination Committee. In the meantime, we present them here for consideration.

REFERENCES

ACKNOWLEDGMENTS

This work was jointly sponsored and executed by the U.S. Department of Energy (DOE) and the U.S. Environmental Protection Agency (EPA). The DOE sponsorship was through the Characterization, Monitoring, and Sensor Technology Crosscutting Program (CMST-CP) and the Mixed Waste Focus Area (MWFA), both of the Office of Science and Technology, Office of Environmental Management. The EPA sponsorship involved the National Risk Management Research Laboratory, Air Pollution Prevention and Control Division, Research Triangle Park (RTP), North Carolina, and the National Exposure Research Laboratory, Air Measurements Division, RTP, and Characterization Research Division, Las Vegas, Nevada. Ames Laboratory is operated by Iowa State University for the U.S. Department of Energy under contract No. W-7405-ENG-82.

DISCLAIMER

This work was completed under funding provided by the U.S. Department of Energy and the U.S. Environmental Protection Agency. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of the authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.