ADVANCING ENVIRONMENTAL RESTORATION

PERFORMANCE AT THE SAVANNAH RIVER SITE;

FY 97 STATUS REPORT

T. Henna

DOE-SRS AMEQ

C. Anderson

DOE-SRS, Director ER

R. Harbert

BSRI, VP and General Manager

ABSTRACT

Three years ago, the Savannah River Site (SRS) environmental cleanup program in Aiken, South Carolina, was criticized for being mired in assessment, analysis, and regulatory paperwork. Active leadership, "breakthrough" management workshops, stretch goals, and focused work by all participants achieved a remarkable turnaround and significant progress in the cleanup of inactive hazardous waste sites at SRS. In addition to the physical results and lower costs, these efforts laid the foundation and established momentum for continued innovation and successful performance. The power of goal setting has driven innovation in the regulatory process, work standards, technologies deployed, and performance-incentive contracting strategies that will have a lasting effect and will ensure the future achievement of Environmental Restoration (ER) at SRS.

BACKGROUND/DISCUSSION

In the aftermath of forty years of production of nuclear materials, SRS must clean up over 470 inactive waste sites ranging from small spills to a 194-acre Radioactive Burial Ground Complex. Prior to 1995, progress in actual remediation of the sites was bogged down in analysis and paper reviews by the site and regulatory agencies. SRS responded by seizing the initiative and directly confronting the need to more clearly focus on cleanup goals for the site and to improve performance through better interaction with the regulators. During the first year after implementing this approach, benefits included achieving $150 million worth of work scope for $125 million and reinvesting the $25 million cost savings back into the environmental restoration program. Field remediation began on 160 additional acres of waste sites during 1996 versus 90 acres started prior to 1996. The rate of groundwater treatment over that of past years was increased by 500%. The program expended 63% of funds on remediation work in FY 96 versus assessment as compared to 40% in FY 95. In 1997, $125 million of work scope was accomplished for $100 million, and the percentage of funding going to remediation activities versus assessment increased to 75%. As a result of the priority placed on safety, this work was performed without a lost time accident. Through 1997, 69 waste sites representing over 80% of the known risk to human health and environment have been completed or placed in the remediation phase. New groundwater treatment methods such as underground airlift recirculation and in situ chemical oxidation are reducing cleanup costs by over 50% as compared to conventional aboveground pump and treat methods.

Figure 1. The ER program at SRS is one of the largest in the country and numbers among the top three in the Department of Energy (DOE). With over 470 individual waste units on a 315 square mile area, SRS ranks high on the National Priority List of remediation sites.

These results are even more remarkable considering that multiple major players were responsible and critical to making things happen in an environment known for multiple regulatory drivers. The Department of Energy (DOE) is responsible for this enormous cleanup effort. Bechtel Savannah River Incorporated, part of the Westinghouse M&O Partnership, manages the ER work. Both Environmental Protection Agency (EPA) and South Carolina Department of Health and Environmental Control (SCDHEC) regulate the cleanup under RCRA and CERCLA. SRS is on the National Priorities List and, in 1993, a Federal Facility Agreement (FFA) for the site was formed between DOE, EPA, and SCDHEC. The FFA established specific cleanup goals and a schedule of compliance for each action. The success of the ER program requires commitment, performance, credibility, and trust by all of the major players involved.

How did such a dramatic change occur? As part of a determined effort to jump-start the ER program at SRS into a high performance organization, a management commitment was made to encourage all participants to work smarter, support innovation and use creative thinking. This entailed some risk taking and leaving comfortable solutions behind. Diverse and empowered teams were established to look "outside the box" and create new ways of doing business. In an effort to meet this challenge, "breakthrough" management workshops were held with the major players to reach common understanding, establish communication channels, and set stretch goals for improvement in critical performance areas. The following are specific examples of how this was accomplished.

BREAKTHROUGH MANAGEMENT

A series of "roll-up-the-sleeves" workshops were conducted designed to look past current performance and address obstacles to achieve breakthrough performance. These productive "think-tank" activities had active representation from both federal and state agencies and the prime contractor and resulted in strengthened relationships and the development of cost-effective methods for ensuring environmental compliance and accelerating cleanup. At the conclusion of the workshop, all parties signed commitment statements of stretch goals. These goals were tangible, measurable, energizing, and highly focused. The goals were considered to be a stretch because the path to achieve these goals was not clearly visible; however, they set a direction to motivate desired progress by all parties.

Figure 2. Chartered by senior management of DOE, EPA, and SCDHEC, a series of Breakthrough Sessions established a joint commitment to performance goals and removed obstacles to success.

The commitment statements addressed goals for the next two years. They included the following:

SRS-ER

EPA-SCDHEC

BETTER WAYS OF DOING BUSINESS

Challenged to reduce the cost of doing business and increasing field remediation, the site aggressively pursued finding low-cost methods of characterizing sites, achieving regulatory compliance, and implementing less expensive remedies that are protective of health and the environment. Many of these better ways of doing business result in long-term cost reduction over the entire clean-up program.

Establishing a mobile laboratory at a central site location to perform field analysis of liquid and volatile organic contaminants led to significant cost and timesaving compared to the past practice of offsite shipment and analysis. The reduction in Remedial Investigation and Feasibility Study (RI/FS) costs is expected to result in savings of approximately $8 million over the next ten years.

Progressive methods were explored to group regulatory requirements to achieve economies of scale. These methods consolidate administrative and documentation requirements for waste sites with similar characteristics and contaminants. One example being developed by the site and the regulators is the Plug-In ROD. The Plug-In ROD is a method of establishing a common solution or remedy for similar waste units at large complex sites. The Plug-In ROD identifies the common remedy and the range of conditions that an individual waste unit must meet to be able to use the common remedy. Once sufficient characterization has been done at a waste unit to show that it meets the common remedy, the unit can "plug-in" to the ROD without the development of a formal RI/FS. The advantages to the plug-in ROD are (1) focused characterization efforts, (2) minimization of documentation required for a waste unit, and (3) acceleration of the schedule for individual waste units. The first application of the Plug-In ROD at SRS is for twenty-two radioactive seepage basins that compose nine operable units. The result is quicker and cheaper remediation of many of the SRS waste sites.

The criteria and standards for environmental work were reexamined. A decision to adopt standards appropriate for the commercial environmental restoration industry to replace costly and inefficient nuclear facility-based standards that had governed SRS since the 1950s provided proper safety to the workers at substantially lower cost.

Working closely with the regulators, groundwater-monitoring requirements were changed using both quantitative and qualitative methods to develop proposed reductions. By reducing the number of monitoring wells, the frequency of sampling and the required analysis, the cost of this activity was reduced from a high of $12.1 million annually in 1993 to $5.4 million in 1997.

Committed to find less expensive yet effective remedies led to a cleanup approach for four coal pile runoff basins, which accelerated the work by 92 months and saved $11 million. Coal pile runoff basins were constructed in the late 1970s to reduce contaminant discharge from seven coal-fired power plants. Site evaluations determined that about 15 thousand tons of coal left in four inactive basins could not be burned in the SRS powerhouses and threatened contamination of the groundwater. Project team members determined that recycling this material could be accomplished at one-third of the original estimate for landfill disposal or soil washing. Coal and coal-laden sediments were removed and transported offsite for processing and reuse in road base construction.

Figure 3. The use of geosynthetic materials during cap construction reduced life cycle costs by $100K per acre at a 55-acre hazardous landfill.

INNOVATION IN TECHNOLOGY

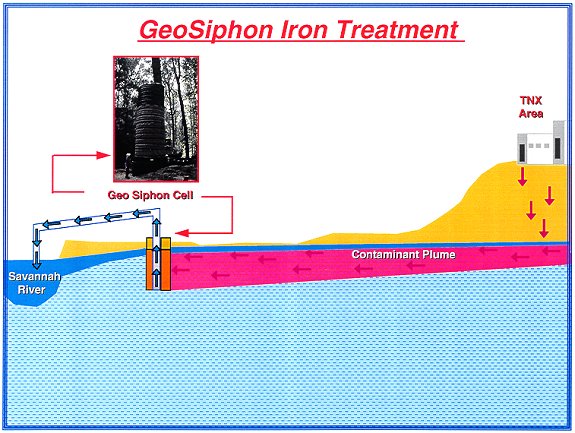

Another approach to being able to accomplish more work for less cost is to apply innovative technologies for environmental restoration. Deployment of innovative technologies has been integrated directly into the restoration program. New technologies such as geosynthetic capping systems, barometric pumping to remove volatile underground contaminants, in situ bioremediation techniques, and in-ground air stripping wells were put in place at a fraction of the time required for previous practices. Fifteen technologies were successfully deployed at 16 sites in 1996 and 12 technologies were deployed on 13 sites in 1997. SRS development costs leading to successful deployment of these technologies was only $3.6 million, yielding a cost benefit of $14 million for this development work.

Figure 4. 23 new/innovative technologies have been deployed in the past two years with a projected SRS cleanup cost reduction of $25M

CONTRACT REFORM

Throughout the nation, DOE has modified its contracting practices to develop a performance reward system for meeting expectations. SRS-ER adopted performance-based incentives that focused and motivated the prime contractor to meet all the regulatory commitments on time and accomplish more work within a given budget. Goals were set to increase the use of outside expertise and resources through subcontracting. New contracting methods were also established to enhance safety performance at all ER work sites.

This approach resulted in exceeding cleanup goals safely and cost-effectively becoming the top priority of the contracting team. The expertise and resources of the best environmental restoration contractors were tapped. The percentage of total program funds directed to subcontractors increased from 40% of the budget in 1995 to 63% in 1996 and 51% in 1997. In addition to broadening the expertise base, the emphasis on using external resources provided additional economic benefit to the communities surrounding SRS and made a substantial contribution to the ongoing development of environmental technologies by the private sector. Using a couple of performance-based incentives focused on key expectation elements along with specific subcontracting goals reinforced the desired direction of DOE management to the contractor.

RECOGNITION OF SUCCESS

Others have recognized the noteworthy performance of SRS ER. Members of the DOE staff have received Vice President Gore's Hammer Award on two separate occasions. The site received four National DOE Pollution Prevention Awards and the White House Closing the Circle Award. SRS was awarded an ISO 14001 certification in 1997. ISO 14001 is the internationally recognized environmental management program. Certification is awarded by an independent third party after an intense review of company policies and practices. SRS was the first in the DOE complex to become certified, and SRS is one of the most complex facilities in the world to be certified.

The result of breaking down the barriers and creating a place for trust and a climate for innovation has also led to public support and acknowledgment. The Aiken Standard newspaper noted these achievements in the May 8, 1996, statement, "…1996 will go down as a banner year for cleanup at the SRS," and in the April 4, 1997, headline announced, "Cost of cleanup reduced at SRS."

CONCLUSIONS

With large federal government environmental cleanup efforts, the level of bureaucracy and the different perspectives of the regulators are often cited as the reason for the failure of improvement efforts. SRS and the regulators have overcome these barriers by:

This "breakthrough" management approach has led to changes in the way that business is done, innovative technology deployment to reduce costs, and using contract reform to motive direction. This extraordinary performance has brought confidence, pride, and satisfaction to many who are involved in SRS ER. With a track record of successfully meeting challenging goals, the site is now prepared to address its life-cycle plans over the next two years and endeavor to meet its regulatory commitments and reduce its total estimated cost by $1 billion! That is a big goal that will result in further innovation and progress. This aggressive goal will capture the new ways of doing business and projected cost reductions due to technology innovations for the entire life of the cleanup program. Focusing on the total estimated cost brings a long-term outlook to doing business in a cost-effective manner.

Significant improvements in the cost, schedule, and performance of federal environmental remediation can be achieved when clear goals are established and the agencies involved agree to work to meet mutual commitments and expectations. The process involves developing the compelling goals, obtaining mutual commitments and expectations, using the goals in all planning phases, and monitoring progress visibly and with all the major players. A compelling goal with no plan in place can be daunting; however, through continuous commitment, like a dream with action, it can become reality. The attraction of being tentative and meek in setting goals is strong; but if it is overcome and bold and ambitious challenges are pursued, the results of a committed team are nothing less than amazing!

BACK