DOCUMENTATION OF ACCEPTABLE KNOWLEDGE FOR LANL PLUTONIUM FACILITY TRANSURANIC WASTE STREAMS

Andrew J. Montoya, Kathleen Gruetzmacher, and Charles Foxx

Nuclear Materials Technology Division

Pamela S. Z. Rogers

Chemical Sciences and Technology Division

Los Alamos National Laboratory

Los Alamos, New Mexico, 87545

ABSTRACT

Characterization of transuranic waste from the LANL Plutonium Facility for certification and transportation to WIPP includes the use of acceptable knowledge as specified in the WIPP Quality Assurance Program Plan.

In accordance with a site-specific procedure, documentation of acceptable knowledge for retrievably stored and currently generated transuranic waste streams is in progress at LANL. A summary overview of the transuranic waste inventory is complete and documented in the Sampling Plan. This document also includes projected waste generation, facility missions, waste generation processes, flow diagrams, times, and material inputs. The second part of acceptable knowledge documentation consists of assembling more detailed acceptable knowledge information into auditable records and is expected to require several years to complete. These records for each waste stream must support final assignment of waste matrix parameters, EPA hazardous waste numbers, and radionuclide characterization. They must also include a determination whether waste streams are defense waste streams for compliance with the WIPP Land Withdrawal Act.

The LANL Plutonium Facility's mission is primarily plutonium processing in basic special nuclear material (SNM) research activities to support national defense and energy programs. It currently has about 100 processes ranging from SNM recovery from residues to development of plutonium 238 heat sources for space applications. Its challenge is to characterize and certify waste streams from such diverse and dynamic operations using acceptable knowledge. This paper reports the progress on the certification of the first of these waste streams to the WIPP WAC.

INTRODUCTION

Acceptable knowledge refers to applying knowledge of the waste based on the materials or processes used to generate the waste. Acceptable knowledge includes information regarding the physical form of the waste, the base materials composing the waste, the nature of the radioactivity present, and the process generating the waste. To meet the waste acceptance criteria for the Waste Isolation Pilot Plant (WIPP), acceptable knowledge characterizations of transuranic waste streams are used to assign matrix parameter categories and EPA hazardous waste numbers and to determine the waste material parameters and radionuclides present.

The Plutonium Facility operated by the Nuclear Materials Technology Division is the largest generator of transuranic waste at Los Alamos National Laboratory. Acceptable knowledge is used to complement sampling and analysis to characterize transuranic waste at the Plutonium Facility. The challenge in documenting acceptable knowledge characterizations of transuranic waste streams generated here arises from the ever-changing mission of the facility and the vast diversity in its research and development and materials processing operations. Waste is generated from plutonium processing in basic special nuclear material (SNM) research to develop, prove, and implement technology for existing and/or future plutonium processing needs, and from the provision of support to national defense and energy programs. The plutonium processing area in the facility currently has about 100 processes operated in over 300 gloveboxes by about 530 plant workers. In addition their has been a constant evolution in requirements and procedures for managing and characterizing the waste since the facility began operation in 1978 which further complicates the effort to document acceptable knowledge for various waste streams.

ACCEPTABLE KNOWLEDGE DOCUMENTATION REQUIREMENTS

The TRU Waste Characterization Quality Assurance Program Plan (QAPP) specifies that generator sites must prepare a written procedure outlining the specific methodology used to assemble acceptable knowledge records. Further, Acceptable knowledge information must be compiled in an auditable record, including a road map for all applicable information. The QAPP and the site-specific procedure, Acceptable Knowledge Documentation, summarize the process of compiling acceptable knowledge using the flow diagram shown in figure 1. This represents the process described here, except for confirmation and audit, which occur only after waste stream approval.

Fig. 1. Compilation of Acceptable Knowledge

The Chemical Science and Technology (CST) Division at LANL coordinates the site's compliance program to ensure that transuranic waste meets the WIPP Waste Acceptance Criteria (WIPP WAC) and TRUPACT II Authorized Methods for Payload Control (TRAMPAC). LANL's transuranic waste generating facilities document their compliance with the site certification program in an interface document that describes the facility's operational and quality procedures for managing transuranic waste as prescribed in the Quality Assurance Project Plan (QAPjP). The TA-55 Transuranic Waste Interface Document (TWID) is used by Plutonium Facility waste management personnel to ensure compliance with the LANL Transuranic Waste Certification Program (TWCP). The Plutonium Facility TWID along with the LANL Acceptable Knowledge Documentation procedure and the LANL TRU Waste Characterization Sampling Plan ensure that the Plutonium Facility transuranic Waste has been characterized and that waste stream designations and numbers and TRUPACT II content (TRUCON) codes are consistent.

PLUTOMIUM FACILITY TRANSURANIC WASTE GENERATING PROCESSES

Plutonium operations have been conducted at building PF-4 of the Plutonium Facility since January 1978. The variety of plutonium handling operations includes:

The manufacturing and research operations performed at the facility in the production of plutonium results in the generation of plutonium contaminated scrap and residues. These are processed to recover as much plutonium as is practical. The Plutonium Facility has extensive capabilities for the extraction and recovery of plutonium from residues and scraps generated from operations at various LANL facilities, other DOE sites, and DOE fabricated radioactive sources from commercial industry. These recovery processes (including nitrate-based, chloride-based, mechanical, and pyrochemical operations), as well as associated maintenance operations, and plutonium research are the sources of transuranic waste generated at the facility.

Because of the variety and complexity of the Plutonium Facility's operations, they are best described using process flow diagrams focused on identifying the points at which transuranic wastes are generated. Figure 2 is an example of such a flow diagram for the nitrate operation, one of the aqueous processes for recovery of plutonium from scrap or contaminated residues. As with other operations, it has been used at the facility since it opened in 1978. Each stage of this operation is actually a collection of sequential or alternative processes. For example, purification may consist of solvent extraction, precipitation, or ion exchange and more than one specific type of ion exchange process may be available. All of the many processes used in the Plutonium Facility are identified with unique process status codes and are tracked by the special nuclear material accountability system as required by DOE. Since about 1987 with the implementation of the enhanced Waste Origination and Disposition Form (WODF) a waste item can be tracked back to the process where it was generated. The correlation of waste items to process status codes is an important factor in characterization of waste streams generated since that time.

Fig. 2. Nitrate Operations

WASTE STREAM CHARACTERIZATION

As part of delineating waste streams by generating processes, acceptable knowledge

documentation must include all available information about potential contamination of the waste caused by:

The most important application of this information is for identification of chemical constituents or contaminants that result in the characterization of the waste stream as hazardous in accordance with the Resource Conservation and Recovery Act (RCRA). Since 1989, use of materials that would render waste streams hazardous has been discontinued wherever feasible. In addition, since 1991, waste stream characterizations as determined in part by waste originator and recorded on WODFs have been documented on LANL Waste Profile Forms (WPF) in accordance with its RCRA operating permit waste analysis plan. For the Plutonium Facility many process specific waste contaminants have been identified by reviewing WPFs and WODFs, examining operational procedures, analyzing chemical and radiological assay data where available, pursuing reports and memos, and interviewing facility personnel responsible for current as well as discontinued processes.

For operations involving well characterized materials, such as metal casting, where only dry processes are used, LANL has characterized waste by-products for WIPP waste acceptance as nonhazardous using acceptable knowledge. Radioisotope distributions in the waste are characterized as being the same as for weapons grade plutonium where contaminants (including decay products), are well known.

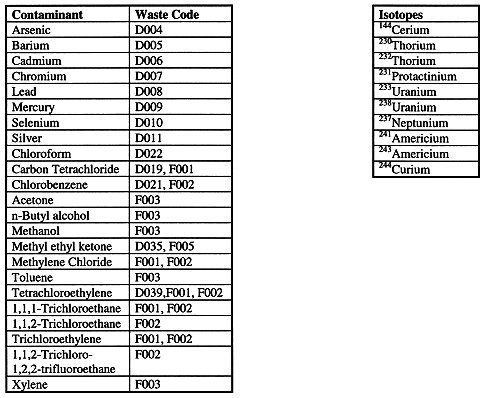

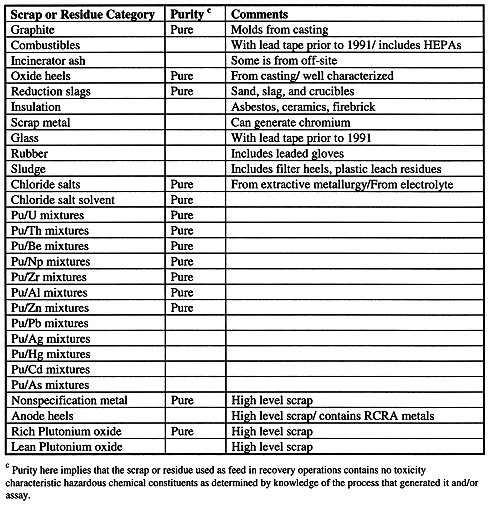

Characterizing waste streams derived from aqueous recovery of residues is more challenging. Reagent inputs and process maintenance and monitoring materials can be well characterized by the process described above. Various processes over time have introduced materials that render waste streams potentially hazardous. Facility personnel have identified these processes and constituents (See Table I) and will use this information to characterize corresponding waste items as hazardous in accordance with the QAPP.a

Table I. Hazardous Chemical and Radiosotopic Contaminants

In addition, it has been determined that some chemical processes, such as acid dissolution, tend to leach process equipment (specifically lead shielding and steel) which contaminate process liquids with metals including lead, chromium, and cadmium. Waste streams generated from these processes are characterized as hazardous. Exceptions to this may include metal and plastic items discarded directly from dissolution or leaching processes or which have been decontaminated prior to discard.

Currently, lead shielding in aqueous process areas and steel equipment in the chloride recovery operation are coated with corrosion resistant materials. Corrosion of stainless steel reaction vessels, storage tanks, and transfer piping continues to contaminate some process liquids. Organic compounds (including solvents) are used in only two end-of-line processes and their hazardous waste by-products are well documented.

It has been necessary to determine what contaminants are contributed to recovery processes by feed materials, specifically residues from other DOE sites. Plutonium Facility personnel have gathered all available data on what off-site residues have been processed, what processes were used on them, and whatever chemical assays are on-hand. Table II shows the typical categories of scrap and residue fed into plutonium recovery operations at the Plutonium Facility. Feed streams with impurities that cannot be fully characterized as nonhazardous with available data are conservatively characterized as hazardous for RCRA codes that may apply.

Table II. Materials Comonly Processed for Plutonium Recovery.

The nuclear materials (i.e. plutonium) in recovery scrap and residue also have contaminants that occur naturally or are products of nuclear decay. The major radioisotope contaminants have been identified (See Table I) and correlated to processes where their concentrations relative to the plutonium in the waste stream can be increased or decreased. Knowledge of the presence of these contaminants and their relative concentrations are important in determining what nondestructive assay techniques are needed to fully characterize the waste for radiological constituents in accordance with the QAPP.b

TIME LINE FOR WASTE STREAM DELINEATION

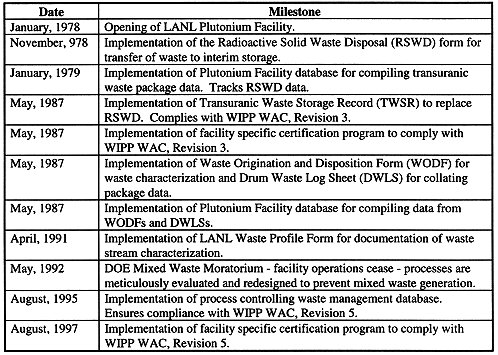

A critical consideration in the delineation and characterization of waste streams is when the waste was generated in relation to the implementation at the Plutonium Facility of waste segregation practices, hazardous waste regulation compliance, WIPP WAC compliance, etc.

Clearly, since the opening of the facility in January 1978 waste management and compliance practices have evolved to a high level of sophistication, just as the regulations, quality criteria, and public expectation have.

To account for the progression in the amount and quality of information available for characterization, major waste streams must be divided into substreams delineated by the time span in which the waste was generated and characterized using the knowledge of the waste available at the time. Table III shows the major milestones in management of transuranic waste at the Plutonium Facility that influence delineation of waste streams.

Table III. Timeline of Plutonium Facility Waste Management Milestones.

CERTIFICATION OF NONMIXED TRU WASTE STREAMS

The DOE Carlsbad Area Office (CAO) evaluated application of the site-specific procedure, Acceptable Knowledge Documentation, as part of the July 1997 audit of the LANL transuranic waste certification Program. The only complete waste stream summary, for the nonhazardous combustible waste stream (TA-55-20), was evaluated as part of the audit. CAO determined that the procedure satisfied the requirements of the QAPP and that the waste stream summary was assembled in accordance with the procedure. There were no findings related to the acceptable knowledge characterization process. Deficiencies in the sample waste stream summary were cited and have been resolved. Deficiencies in compliance with the WIPP QAPP generally resulted in reclassification of some of waste stream TA-55-20 into waste stream TA-55-19. TA-55-19 is for hazardous combustible debris.

Based on the July audit and related corrective actions, the CAO on September 17 announced that Los Alamos National Laboratory has met all program requirements to characterize, certify, and ship transuranic waste to WIPP.

Recently, the New Mexico Environment Department (NMED) notified the DOE that WIPP would not be issued a Part B operating permit by its scheduled opening in May, 1998. WIPP, in turn, notified TRU waste generator sites that it would only accept shipments of nonhazardous TRU when opened and until NMED issues a permit. As a consequence, LANL has reprioritized its schedule for characterization of its waste streams. Since TA-55-20 had decreased in volume and identification containers meeting its criteria became more difficult, LANL found it necessary to identify another nonhazardous waste stream to characterize and certify for initial shipments to WIPP.

LANL's priority for WIPP WAC certification is now the 238Pu contaminated TRU waste stream generated by heat source fabrication at TA-55 from 1979 through 1997. (No identifier has been assigned to this waste stream to date.) 238PuO2 was processed for heat source fabrication for the defense related Milliwatt Generator Project as well as NASA required units. The latter included the General Purpose Heat Source (GPHS) developed in the late 70's and early 80's and produced for the Cassini mission from 1992 to 1997. The Lightweight Radioisotope Heater Unit (LWRHU) developed in 1979 and 1980 was produced in 1984 and 1985 for the Galileo mission and the Cassini mission from December 1993 through 1995. 238Pu for all these efforts was produced, separated, and purified at Savannah River Site. TA-55 processes are essentially dry processes that do not purify further the 238PuO2 fuels. Extensive analytical data on the feed material and process knowledge are available to document the acceptable knowledge characterization of the waste stream as nonhazardous.

The 238Pu processes at TA-55 use no organic solvents and the oxide feed materials do not contain any organics. In any case, organics would be boiled off or destroyed by the high temperature production processes.

Although acid solutions are used to decontaminate fuel clads, rags presented for disposal have too little liquid to be characterized as corrosive. Excess solution is discharged to a radioactive liquid waste treatment plant. The only other processing solution is a cement for sealing the graphite aeroshell of the LWRHU heat source assembly. It does not contain any material that would be RCRA-regulated on disposal.

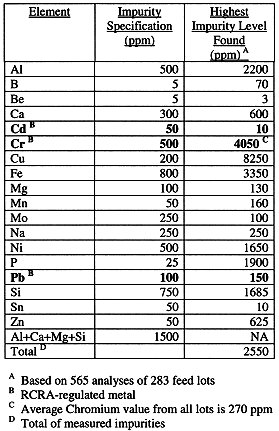

Savannah River did not introduce RCRA toxic metals arsenic, mercury, and selenium into their purification processes either directly or as impurities in the reagents. There is no reason to expect those metals to be present in the oxide feed used at LANL as they and their oxides would volatilize in the high temperature processes or separate from product in ion exchange and precipitation. Oxide metal feed or seasoned granules were analyzed for numerous metals including cadmium, chromium, lead, and silver to verify compliance with impurity specifications. As an example, Table 4 shows the specifications and maximum reported impurity levels in General Purpose Heat Sources on Cassini. Analysis of chemical assay data and the applicable 238Pu discard limits (The highest plutonium discard limit for 238Pu is 18.6g/kg waste associated with the combustibles waste stream.) has shown that the 238Pu waste streams do not contain these metals in concentrations exceeding the applicable regulatory limits. In addition, taking into account that the lowest plutonium content oxide feed processed at LANL contained 83.3% 238Pu (wt% 238PuO2 exceeds 94.4%, therefore wt% BaO cannot exceed 5.56%) it was demonstrated that Barium concentration is below the regulatory limit in waste meeting the discard limits for Pu content. Further, the RCRA metals are not reagents in the processing steps.

Table IV. Maximum Possible Impurity Levels in

General Purpose Heat Sources on Cassini

Some mixed waste does arise because the waste matrix is hazardous. The waste materials that fall into this category are leaded gloves and any lead metal used in the gloveboxes as shielding. Mixed waste is also generated in the form of hydroxide cakes, which like lead metal and leaded gloves must be separated from the nonhazardous waste discussed above.

290 55-gallon drums of 238Pu waste generated since 1987 and available in above ground storage have been identified. As much as 20% of this volume is mixed or cannot meet the TRUPACT II heat decay limits for shipment to WIPP. Approximately, 25% of these drums can be certified without repackaging. The remaining drums will have to be opened for sorting and repackaging to meet all characterization and certification requirements.

STATUS OF ACCEPTABLE KNOWLEDGE DOCUMENTATION PROJECT

Characterizing waste streams using acceptable knowledge in compliance with the WIPP QAPP is an essential element of LANL's authority to operate its WIPP transuranic waste program. Once a waste stream summary is completed waste payload containers that meet the characterization profile can be assigned to that waste stream. A waste stream profile will be submitted via the WIPP Waste Information System (WWIS) to the WIPP waste acceptance official for approval. When waste stream approval is received certification data packages for individual payload containers from the waste stream can be submitted via the WWIS for acceptance. Site certification officials can then arrange shipments to WIPP using the TRUPACT II.

Waste stream TA-55-19 consists of the hazardous portion of the combustible debris generated from facility and equipment operations and maintenance (i.e.; from all operations in the Plutonium Facility) generated since 1978. TA-55-20 is the nonhazardous counterpart. The acceptable knowledge characterization of these waste streams is determined in part by knowledge of the process status code, which were tracked for waste items since 1987. Containers of combustible debris which do not consist entirely of waste items from processes that can be documented as not generating hazardous waste must be characterized as hazardous and assigned to waste stream TA-55-19. It is expected that very few drums can be assigned to waste stream TA-55-20 because of the commingling or lack of process status codes within waste containers. Together the two waste streams account for about 4500 containers (approximately 940 cubic meters) of LANL's TRU waste inventory and make up the largest pool of similar matrix debris from the Plutonium Facility available for certification. Unless another nonhazardous waste stream can be identified for reprioritization, combustible debris will be certified next after the nonhazardous 238Pu.

In the meantime, additional waste stream summaries and waste stream profiles will be generated in accordance with the Acceptable Knowledge Documentation procedure. LANL expects that by the opening of WIPP in May 1998 it will have a sufficient number of containers from the 238Pu waste stream to support regular shipments for some time. Once WIPP's RCRA operating permit is issued, containers from several waste streams will be certified and available for shipment. Initially, all approved LANL waste streams will consist of Plutonium Facility waste, as it is the only facility with an interface document approved by the site certification program.

REFERENCES

DOE Consolidated TRUPACT-II Content Codes (TRUCON) and List of Chemicals and Materials in TRUCON (Chemical List). DOE/WIPP 89-004, Carlsbad, New Mexico, U.S. Department of Energy, Carlsbad Area Office (1996a)

DOE Transuranic Waste Characterization Quality Assurance Program Plan. CAO-94-1010, Current Revision, Carlsbad, New Mexico, U.S. Department of Energy, Carlsbad Area Office (1995a)

DOE Waste Acceptance Criteria for the Waste Isolation Pilot Plant, Revision 5. DOE/WIPP-069, Carlsbad, New Mexico, U.S. Department of Energy, Carlsbad Area Office (1996c)

NRC Safety Analysis Report for the TRUPACT-II Shipping Package. Docket 9218, Washington, D.C., U.S. Nuclear Regulatory Commission (1994)

LANL AR 10-9, Waste Profile Form

Los Alamos National Laboratory Transuranic Waste Certification Plan, PLAN-CSTDO-004 (1996b)

Los Alamos National Laboratory Transuranic Waste Characterization Quality Assurance Project Plan, CSTDO-PLAN-002 (1997b)

Los Alamos National Laboratory Transuranic Waste Characterization Sampling Plan, TWCP-PLAN-0.2.7-001

LANL Acceptable Knowledge Documentation, TWCP-QP-1.1-021

LANL TA-55 Transuranic Waste Interface Document, WM-TA55-TWID

FOOTNOTES

a

QAPP requires that when a toxicity characteristic hazardous constituent is identified as reasonably expected to be in the waste stream, no judgement, using acceptable knowledge, will be made regarding the concentration of the constituent. Analytical data must be used to demonstrate that concentration is below regulatory level for disposal.b

QAPP requires that for waste streams contaminated with radioactive materials of variable or unknown isotopic composition, a method independent of acceptable knowledge be used to determine isotopic ratios.