FLAMMABILITY TESTING OF SIMULATED MIXED WASTE

CONTAINER HEADSPACE GASES

C. A. Loehr and S. M. Djordjevic

Benchmark Environmental Corporation

Albuquerque, New Mexico

M. J. Connolly and K. J. Liekhus

Lockheed Martin Idaho Technologies Company

Idaho National Engineering and Environmental Laboratory

Idaho Falls, Idaho

I. A. Zlochower and K. L. Cashdollar

National Institute of Occupational Safety and Health Pittsburgh Research Center

Pittsburgh, Pennsylvania

ABSTRACT

The Safety Analysis Report for the Transuranic (TRU) Package Transporter-II set limits for gas generation rates, wattage, and flammable volatile organic compound (VOC) concentrations in TRU waste containers that will be shipped to the Waste Isolation Pilot Plant. A flammability testing program was conducted at the National Institute for Occupational Safety and Health Pittsburgh Research Center to investigate the potential flammability of gases found in TRU waste containers. This paper describes the design, results, and analyses of the tests that establish mixture lower explosive limits for the types of gas mixtures observed in TRU waste. The experimental test results were compared to predictions from a number of methods, including Le Chatelier, a modified Le Chatelier, group contribution, and the American Society for Testing and Materials CHETAH software. Test results were also used to develop a linear regression model that utilizes the chemical group concept. The experimental results agree closely with the predictions obtained from the group contribution method. The linear regression model exhibits a good fit with the experimental data. Based on test results analysis, a model that accounts for the flammability characteristics of gas mixture components and provides assurance that predictions and associated errors are appropriately bounded by test results has been selected for use in the U.S. Department of Energy's Flammability Assessment Methodology Program. The program showed that concentrations of flammable VOCs in TRU waste containers can be increased from the current 500 ppm limit by decreasing the allowable concentration of hydrogen. Implementation of the program would thus allow more containers to be shipped without treatment or repackaging of the waste.

INTRODUCTION

The Flammability Assessment Methodology Program (FAMP) was established to investigate the flammability of gas mixtures found in transuranic (TRU) waste containers. The FAMP results provide a basis for increasing the permissible concentrations of flammable volatile organic compounds (VOCs) in TRU waste containers. The FAMP results will be used to modify the Safety Analysis Report for the TRUPACT-II Shipping Package (TRUPACT-II SARP) (U.S. Nuclear Regulatory Commission [NRC] 1996) upon acceptance of the methodology by the NRC. Implementation of the methodology would substantially increase the number of drums that can be shipped to the Waste Isolation Pilot Plant (WIPP) without repackaging or treatment.

Central to the program was experimental testing and modeling to predict the gas mixture lower explosive limit (MLEL) of gases observed in TRU waste containers. The flammability experimental work, conducted by the National Institute of Occupational Safety and Health, Pittsburgh Research Center (PRC), was successful in measuring MLELs for mixtures of VOCs and flammable gases (i.e., hydrogen and methane) found in TRU waste drums. The experimental data supported selection of an MLEL model that was used to construct screening limits for flammable VOCs and flammable gas concentrations. The MLEL values predicted by the model for individual drums will be utilized to assess flammability for drums that do not meet the screening criteria. Finally, the predicted MLEL values will be used to derive acceptable gas generation rates, decay heat limits, and aspiration time requirements for drums that do not pass the screening limits. The program results demonstrate that an increased number of waste containers can be shipped to the WIPP within the flammability safety envelope established in the TRUPACT-II SARP.

BACKGROUND AND OBJECTIVE

A requirement for use of the TRU Package Transporter-II (TRUPACT-II) is that the concentration of flammable gases (i.e., hydrogen and methane) must not exceed five percent (by volume) during a 60-day shipping period after the TRUPACT-II is sealed. In addition, the total concentration of potentially flammable VOCs is limited to 500 ppmv in the headspace of a waste container. The FAMP was established with the intent of providing a basis for increasing the permissible flammable VOC concentration limits in the TRUPACT-II, thereby increasing the number of drums that may be shipped without treatment or repackaging. To meet the objective, the FAMP investigated the flammability of gases in TRU waste; designed and tested a series of gas mixtures; selected a model for predicting the MLEL of gases in TRU waste drums; developed screening limits for flammable gas and VOC concentrations; developed a strategy for determining flammability of gases in drums that do not pass screening limits; and delineated the approach for determining acceptable gas generation rates, decay heat limits, and aspiration time requirements.

FLAMMABILITY EXPERIMENTS

The design for flammability experiments focused on investigating the following classes of compounds: flammable gases, nonflammable VOCs, and three groups of flammable VOCs (based on VOC lower explosive limits [LELs] and structural characteristics of the compounds). Hydrogen was used as the flammable gas and carbon tetrachloride was used to represent nonflammable VOCs. VOCs were selected based on prevalence in TRU waste and physical characteristics that facilitated testing.

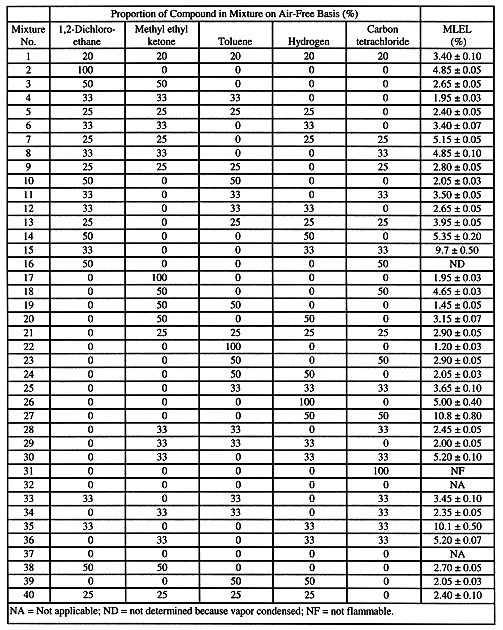

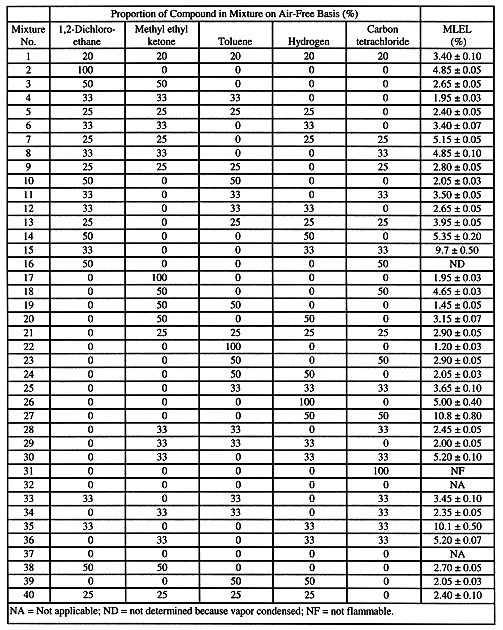

The lowest flammable concentrations in air of all mixtures specified in the experimental design were determined in a 19-L, heavy-walled, stainless steel test chamber using a strong spark ignition source. Partial pressures of the VOC and hydrogen components were used to determine test mixture composition and concentration in air for MLEL determinations. MLELs are based on pressure versus component concentration data plots. Except for 1,2-dichloroethane, LELs of individual VOCs were within the narrow range of literature values (Kuchta 19875). Experimental MLELs generally agreed with calculated values for the mixtures to within 10 percent (Zlochower et al. 1997). Table I gives experimental results.

The largest uncertainty in the MLEL determinations was due to a gradual increase in explosion pressure with hydrogen concentration and the dominance of hydrogen in some mixtures - particularly the hydrogen and carbon tetrachloride mixture - which combines the lightest, most diffusible molecule (hydrogen) with the heaviest VOC (carbon tetrachloride) selected for the experimental tests. The flammability of equimolar mixtures containing hydrogen are expected to be more influenced by hydrogen because of its diffusibility and reactivity as a fuel. This behavior is greatest when other mixture components are much heavier and slower than hydrogen, such as the halogenated components carbon tetrachloride and 1,2-dichloroethane. The other hydrogen-containing mixtures and the pure VOC mixtures (excluding hydrogen and carbon tetrachloride) show a sharp discontinuity at the flammability boundary and, therefore, have more well-defined MLEL and LEL values (Zlochower et al. 1997).

METHODOLOGY IMPLEMENTATION

Model Development, Evaluation, and Selection

Central to FAMP activities is the use of a model for predicting MLELs in TRU waste containers. Seven different models or methods were evaluated. The models include the original method of Le Chatelier (Kuchta 1985); a modified Le Chatelier method (i.e., Le Chatelier with Nonflammable Mole Fraction) based on accounting for the nonflammable VOC proportion; a group contribution factor (Group) method, a Flammable Group method, and a Group Corrected method that are all derived using the Group method for a single

Table I. Experimental MLEL Results for Test Mixtures.

compound (AIChE 1994); and predictions made using the ASTM CHETAH beta version 7.1 code (ASTM 1997). The experimentally determined MLELs were used to develop a seventh model, a Linear Regression model, to predict MLELs. The linear regression model was evaluated in two forms - one using logs of test MLELs, and one using the original, untransformed MLELs. In subsequent text, these models are referred to as Le Chatelier Original, Le Chatelier with Nonflammable Mole Fraction (or modified Le Chatelier), Group, Flammable Group, Group Corrected, ASTM CHETAH, Linear Regression (Ln), and Linear Regression, respectively. In addition, the Group and Linear Regression (Ln) models were adjusted based on experimental error to derive models that are conservative in predictions. The adjustments are based on absolute experimental error and relative experimental errors, resulting in the following four additional models, referred to as Group Absolute Adjusted, Linear Regression (Ln) Absolute Adjusted, Group Relative Adjusted, and Linear Regression (Ln) Relative Adjusted.

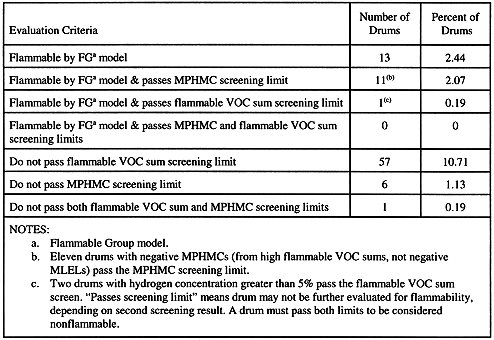

Model predictions for the test mixtures were compared to MLELs determined in flammability testing (Table II). Statistics on measures of the degree and consistency of agreement between predicted and test MLELs were generated (Table III). An evaluation of the models was also performed using innermost layer concentrations for 532 drums characterized under the TRU waste characterization programs at the Idaho National Engineering and Environmental Laboratory and the Rocky Flats Environmental Technology Site.

Statistics show that the linear regression models and, to a lesser extent the Group and Group Corrected models, are unbiased and have relatively low errors. Bias-adjusted Linear Regression (Ln) and Group models consistently underpredict test MLELs by the largest amount. The Flammable Group and Le Chatelier models are also fairly consistent underpredictors. The ASTM CHETAH model is a large underpredictor with high error.

Except for the linear regression models, the models tended to overpredict the 50 percent hydrogen and 50 percent carbon tetrachloride test MLEL value. This value, as well as the 100 percent 1,2-dichloroethane value, had high influence measures for the linear regression models. Log transformation of the test MLELs prior to regression reduced the influence of specific test values in the regression and improved the ability of the models to meet necessary model assumptions on error distributions.

In applying the models to actual drum data, it was found that some methods resulted in unrealistic MLELs. For instance, all methods except the Flammable Group method resulted in extremely high MLELs predicted for some drums. Also, group contribution methods that accounted for nonflammable constituents resulted in negative MLELs in some instances. Because such anomalous MLEL values do not complement the flammability assessment methodology, where the flammable VOC and flammable gas characteristics need to be examined separately, the methods that predict unrealistic MLELs are not appropriate for use. For this reason and because of favorable results in the experimental-based evaluation, the Flammable Group model was used to develop screening limits and is included in the strategy for evaluating individual drums.

Development of Screening Limits

Conservative screening limits were developed to segregate containers with no potential for flammability from those requiring more detailed evaluation. The screening limits are based on statistics for gas concentrations in innermost confinement layers of drums predicted to be nonflammable based on MLELs predicted using the Flammable Group model. Screening limits were developed for (a) flammable gas concentration, and (b) flammable VOC concentration for each waste type (Table IV). Statistics on the performance of the screening limits relative to drums determined to be flammable (Table V) show that no drums determined to be flammable (by MLEL modeling) pass both screening limits; therefore, no flammable drums would be deemed nonflammable.

Table II. Results of Predictive Mixture Lower Explosive Limits Modeling

Table III. Statistics for Parameters Used in the Experimental-Based Evaluation

Table IV. Screening Limits by Waste Type

Table V. Screening Limits Comparison

Strategy for Drum Flammability

Because of the conservatism in screening limits, some drums will exceed one or both limits, but may not be flammable. Therefore, drums exceeding a limit will be subjected to one or two additional stages of evaluation. The first stage involves using the selected MLEL model to predict the drum-specific MLEL and comparing the sum of steady-state innermost confinement layer flammable gas and VOC concentrations to the MLEL. If the drum concentration sum exceeds the MLEL, flame testing of gases that represent the steady-state innermost layer gas concentration in the drum may be performed. Figure 1 gives the strategy for drum flammability evaluations.

Strategy for Determinations of Drum Decay Heat and Aspiration Time Requirements

For drums that pass the screening limits, the applicable screening limit for flammable gas concentration is used to determine the acceptable flammable gas generation rate, decay heat limit, and required aspiration time. For drums that fail a screening limit, the maximum permissible flammable gas generation rate is calculated for the drum and used to determine the allowable decay heat and aspiration time using the TRUPACT-II SARP methodology. The drum must satisfy the decay heat and aspiration requirements prior to shipment.

CONCLUSIONS

The flammability experimental work was successful in measuring MLELs for mixtures of VOCs and flammable gases found in TRU waste drums. The experimental data supported selection of an MLEL model, the Flammable Group model, which was used to construct limits for flammable VOC and flammable gas concentrations. The limits are higher than the current 500 ppmv limit for waste types with relatively high concentrations of flammable VOCs. For the 532 drums examined, more than 20 percent have flammable VOCs in innermost layers of confinement that exceeded the 500 ppmv limit, but only 2.44 percent were flammable by the conservative Flammable Group model. All drums that were classified as flammable did not pass one or both screening limits, which provides evidence that the screening limits are a reliable, though conservative, indicator of flammability. Overall, the program demonstrates that an increased number of waste containers can be shipped to the WIPP within the flammability safety envelope established in the TRUPACT-II SARP.

REFERENCES

1. NRC, Safety Analysis Report for the TRUPACT-II Shipping Package, Revision 16, NRC Docket No. 9218, Washington, D.C., U.S. Nuclear Regulatory Commission (1996).

2. ZLOCHOWER ET AL. (I. A. ZLOCHOWER, K. L. CASHDOLLAR, AND G. M. GREEN), Final Report, Measurements of the Lower Flammability Limits of Mixtures of Volatile Organic Compounds Plus Hydrogen in Air, Pittsburgh, Pennsylvania, National Institute for Occupational Safety Health, Pittsburgh Research Center (1997).

3. J. M. KUCHTA, Investigation of Fire and Explosion Accidents in the Chemical, Mining, and Fuel-Related Industries - A Manual, Bulletin 680, Washington, D.C., PRC, U.S. Department of the Interior (1985).

4. AIChE, Procedure B: Method for Estimating Lower Flammability Limit of Pure Compounds in the Data Prediction Manual. New York, New York, American Institute of Chemical Engineers (1994).

5. ASTM, CHETAH, Version 7.1, The ASTM Computer Program for Chemical Thermodynamic and Energy Release Evaluation (NIST Special Database 16), 3rd Edition, ASTM Data Series DS51 B. Philadelphia, Pennsylvania, ASTM Subcommittee E27.07 on Estimation Methods of ASTM Committee E-27 on Hazard Potential of Chemicals (1997).

Fig. 1. Strategy for Drum Flammability Evaluations